Working Principle and Characteristics of Electric Permanent Magnet Chuck Controller

2021-11-12

Abstract

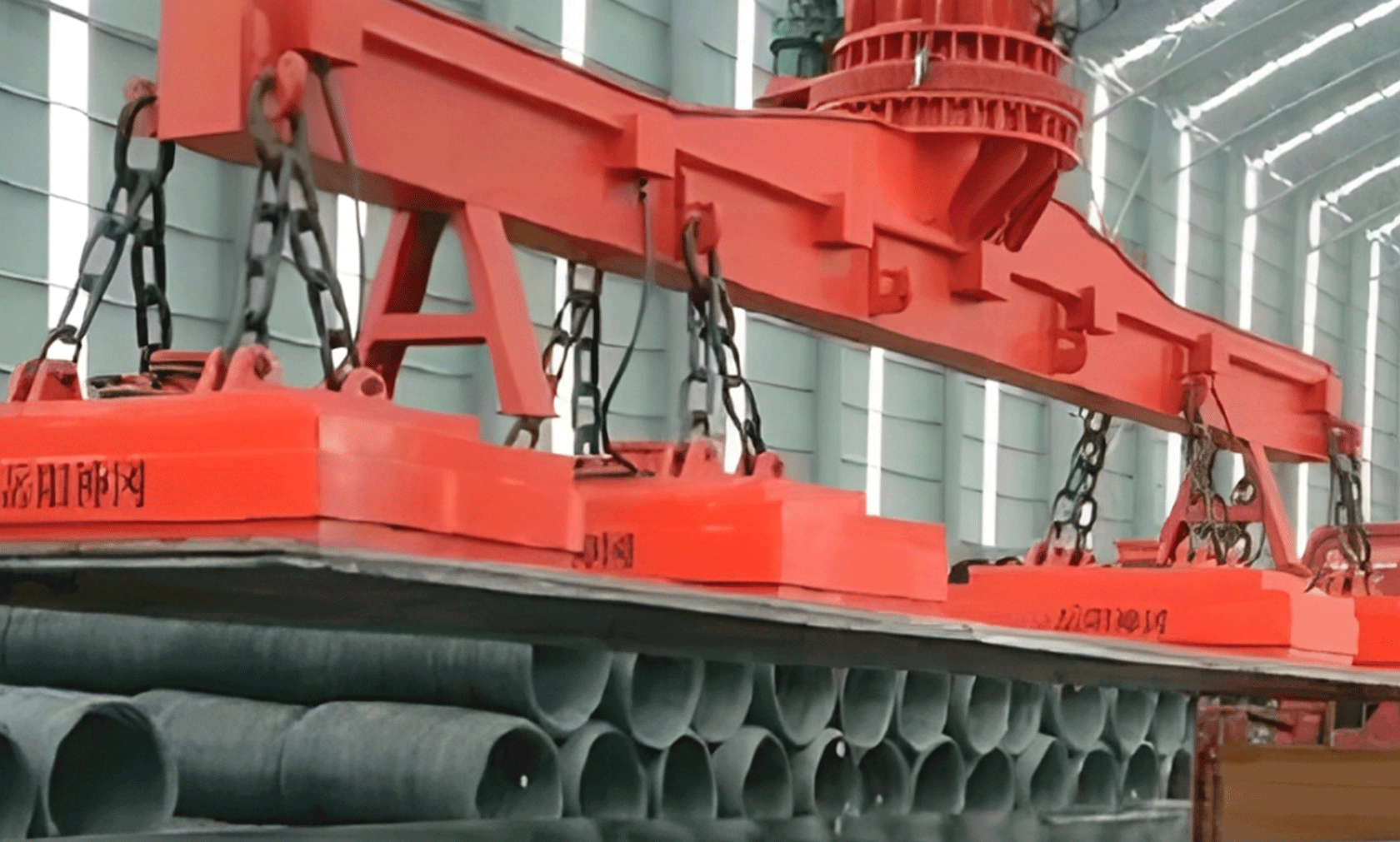

The principle of the electric permanent magnet suction cup controller is to use an AC voltage of 220V to step down through a transformer, rectify it into DC through a rectifier, and then enter the suction cup through the control device to achieve demagnetization. Features of the charging and demagnetization controller: The electric permanent magnet suction cup controller has a complete overcurrent protection function, which can protect the charging and demagnetization controller well without damage even if a short circuit fault occurs in the electromagnetic suction cup. After fault protection, the output is cut off, and even if power is turned on again, the fault will not reoccur. After troubleshooting, the controller can be manually reset to restore output.

The electric permanent magnet suction cup controller has the following features:

Complete safety protection function: The spindle linkage is achieved through unlocking input contact signals and magnetization state output contacts, with adjustable charging current overcurrent protection and undercurrent alarm functions. The electric permanent magnet suction cup is not only powered on at the moment of charging;

Reliable operation, simple operation: All set parameters and operating states can be monitored through the main panel, with a power frequency automatic tracking function, and can safely operate within the power supply voltage of AC250-420V (suitable for AC380V power supply) or AC150-250V (suitable for AC220V power supply) in the frequency range of 45-65Hz;

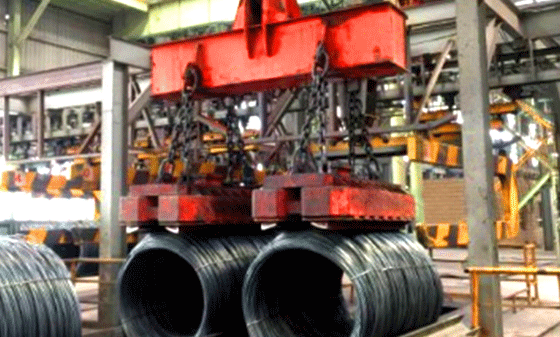

Flexible configuration, convenient to use: This product has 1-4 channels, which can control 1-4 electric permanent magnet suction cups (or 1-4 electric permanent magnet suction cup group units). Each channel can be set to turn on or off as needed, and through demagnetization or magnetization operations, effectively remove residual magnetism from the surface of the workpiece.

There are various optional control interfaces to meet various online control requirements. There are optional remote control or PLC interfaces. Through the optional data communication function, synchronization of up to 64 controllers can be achieved to complete multiple tasks. Matrix control or linkage control of up to 512 electric permanent magnet suction cups meets the control requirements of large and extra-large machining equipment or mechanical production lines for chucks.

The design of the electric permanent magnet suction cup usually uses two different magnetic materials as the main magnets, one being a high coercivity permanent magnet material as the main magnet; the other being a medium coercivity magnetic steel material as the reversible magnet. The magnetic circuit is formed by the magnetic yoke between the two magnets, and then the magnetic field direction of the reversible magnet is changed by the electromagnetic field generated by the pulse current in the excitation coil, achieving control and conversion of the internal magnetic circuit of the suction cup, thus achieving demagnetization (DEMAG) or magnetization (MAG) externally.

When the excitation coil is positively excited, the polarity direction of the reversible magnet of the electric permanent magnet suction cup causes both the main magnet and the reversible magnet to have magnetic flux flowing out; an external workpiece forms an external circuit, which is in a magnetization state; when the excitation coil is negatively excited, the polarity direction of the reversible magnet reverses, forming an internal circuit with the reversible magnet, with no magnetic flux flowing out externally, and no magnetic flux passing through the external workpiece, thus being in a non-magnetic state, and the electric permanent magnet suction cup is in a demagnetization state.

Related News

The company will continue to develop and innovate with the enterprise spirit of worrying about customers first and enjoying the happiness of customers later, and strive to become a giant of modern enterprises. Welcome all friends to visit and guide our company!

Address: Liji Avenue, Junshan Industrial Park, Yueyang City, Hunan Province

Fax: 0730-8647119