The importance of analyzing the diversification of production of lifting electromagnet suction cups.

2023-09-12

Abstract

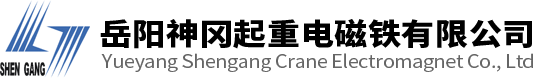

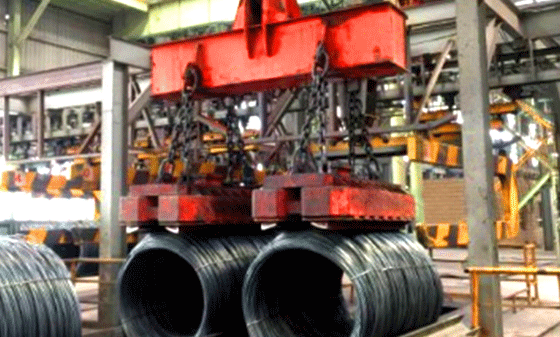

The lifting electromagnet suction cup is divided into rectangular suction cup electromagnets, circular suction cup electromagnets, square electromagnet suction cups, etc. The applications of suction cups are very extensive. They are particularly used in the machining industry, and there are also some industrial suction cups (such as crane suction cups) that can be applied in foundries, large steel mills, and other workpieces that are difficult for machines to grasp. They are indispensable mechanical tools in the handling process (such as electromagnetic suction cups, electromagnetic suction cups, etc.).

There are many classifications of lifting electromagnet suction cups, with the crane being one of the more widely used, also known as suction cup electromagnet cranes, etc. The manufacturing process of suction cup electromagnets is very precise. The adsorption force varies with different specifications. The average adsorption force can reach 10 to 12 kilograms per square centimeter. The adsorption surface should match the suction cup's adsorption surface. Otherwise, it will greatly reduce the efficiency of the suction cup electromagnet and decrease the suction force of the suction cup.

The important part of the suction cup electromagnet mainly involves the development and improvement of the overall use of AN, and the improvement of the leakage and waterproof performance of the suction cup electromagnet. After strengthening the waterproof function of the suction cup electromagnet based on the original design, it can be submerged for several months without a drop of water entering. After successful experiments, it was put into mass production.

The lifting electromagnet suction cup consists of a coil, yoke, iron core (pole), and pole lamp, forming a closed magnetic circuit. The energized conductive coil (coil/winding) generates a certain magnetic field, and the iron core (pole) rearranges the irregular ferromagnetic metal atoms inside in a regular manner under the influence of the external coil magnetic field, pointing in one direction, magnetizing to increase magnetic flux, thereby generating a considerable amount of magnetic flux between the iron core, yoke, and air gap.

Generally speaking, the electromagnetic field formed by the electromagnet is related to the amount of current, the number of coils, and the ferromagnetic body at the center. When designing the electromagnet, attention should be paid to the distribution of the coils and the selection of the ferromagnetic body, using the size of the current to control the electromagnetic field. Because the materials of the coils have resistance, it limits the size of the magnetic field that the electromagnet can generate, but with the discovery and application of superconductors, there may be opportunities to exceed the existing limitations.

The previous one-

Related News

The company will continue to develop and innovate with the enterprise spirit of worrying about customers first and enjoying the happiness of customers later, and strive to become a giant of modern enterprises. Welcome all friends to visit and guide our company!

Address: Liji Avenue, Junshan Industrial Park, Yueyang City, Hunan Province

Fax: 0730-8647119