How to prevent the lifting electromagnet hook from swaying back and forth

2023-09-12

Abstract

1. How to prevent the lifting electromagnet hook from swinging back and forth

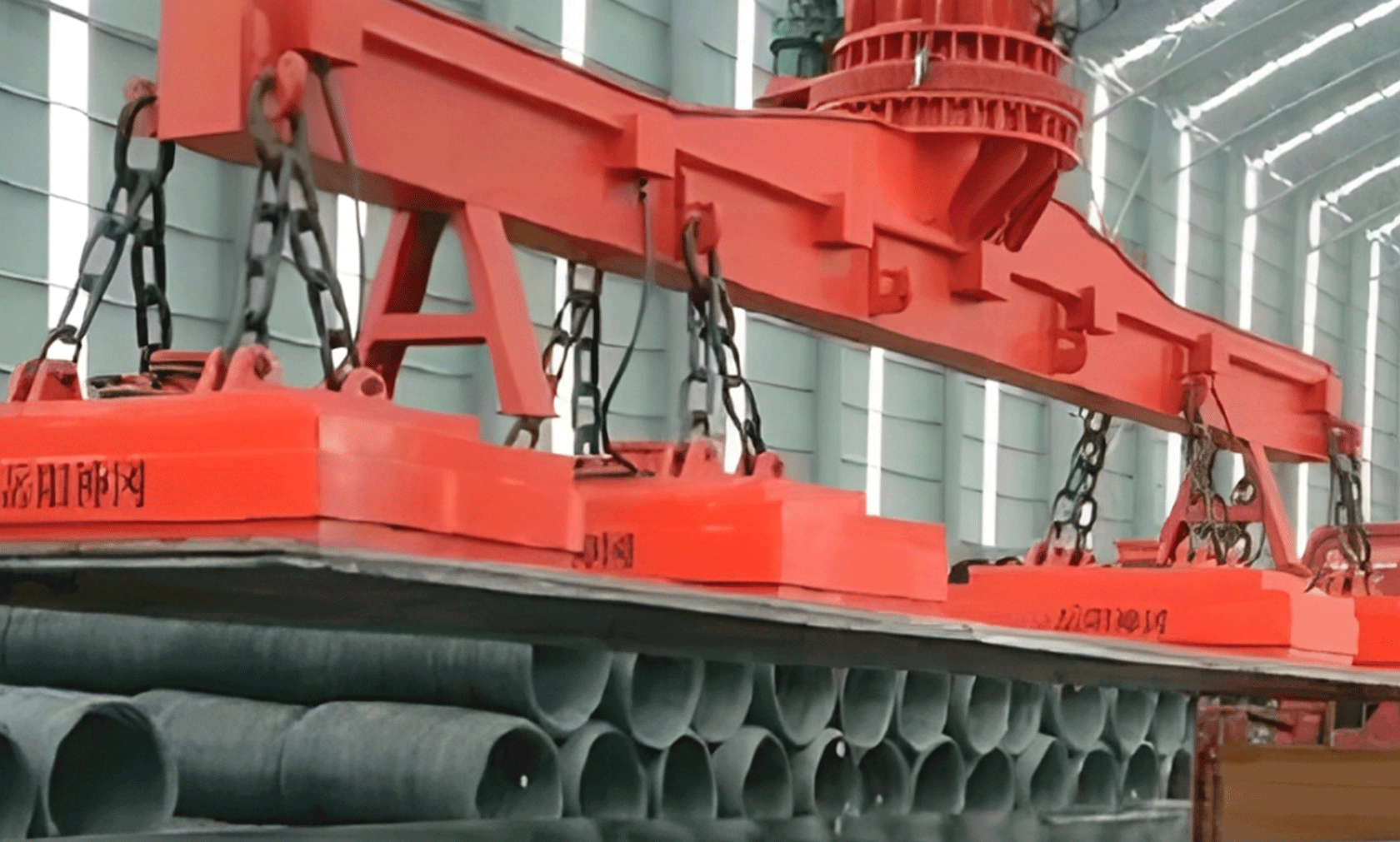

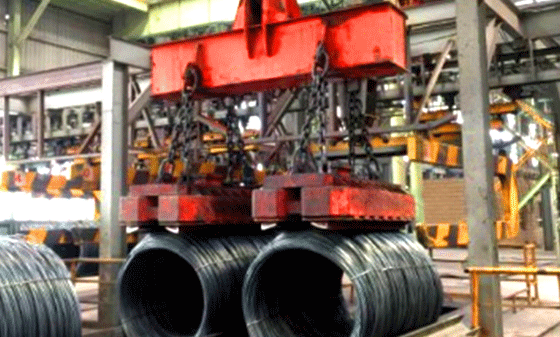

It is often used in some electromagnets to collect and transport iron filings. During the operation of the lifting electromagnet, the staff must operate the equipment carefully because the hook of the lifting electromagnet is suspended and drooping, making it easy to swing back and forth. Let's learn how to prevent the hook of the lifting electromagnet from swinging back and forth.

1. To prevent the lifting electromagnet hook from swinging, the driver should follow the operating procedures, correctly position the crane during operation, slowly start the trolley step by step, appropriately adjust the trolley's brakes, and try to make the lifting operation smooth and stop smoothly. When lifting items, short rope loops should not be chosen. By taking these measures, the swinging of the lifting electromagnet hook and the object can be prevented.

2. Elimination of hook swinging: When swinging occurs due to improper operation of the lifting electromagnet, the "follow the vehicle" method should be used to eliminate the swing. For example, when the hook swings in the same direction, before the swing reaches the Z value, the vehicle body suddenly accelerates in the same direction, forcing the hook to stop moving and be in a leading position. At this time, the speed of the vehicle body is close to or equal to the horizontal forward speed of the hook, and the relative speed between the two is almost zero, allowing the hook to stabilize. 3. Starting the large vehicle "follow the vehicle" can eliminate lateral swinging; starting the small vehicle "toe vehicle" can eliminate longitudinal swinging, and starting both the large and small vehicles "follow the vehicle" can eliminate diagonal swinging.

2. Selection considerations:

1. When the temperature of the material being lifted is below 100 degrees, please choose a normal temperature lifting electromagnet; if the temperature exceeds 100, please choose a high-temperature lifting electromagnet. If the temperature exceeds 600 degrees, please choose an ultra-high temperature lifting electromagnet.

2. When the power-on duration exceeds 60%, please choose a high-frequency lifting electromagnet.

3. When lifting materials in water, please choose a diving type (diving depth not exceeding 100m). The parameters of the diving lifting electromagnet are the same as those of the normal temperature electromagnet. If the user needs a diving type, please specify when ordering.

4. Environmental temperature: Normal temperature -5~40. High temperature -5~50. Altitude not exceeding 2000 meters.

5. Equipment matching: When using a single unit, the rectification control equipment and auxiliary equipment should be selected based on the power (current) consumed; when multiple units are used together, they should be selected based on the total power consumption (current) of the units used together.

Related News

The company will continue to develop and innovate with the enterprise spirit of worrying about customers first and enjoying the happiness of customers later, and strive to become a giant of modern enterprises. Welcome all friends to visit and guide our company!

Address: Liji Avenue, Junshan Industrial Park, Yueyang City, Hunan Province

Fax: 0730-8647119