Detailed explanation of lifting and bundling bar material with electric lifting magnets

2021-11-09

Abstract

The basic principle of lifting electromagnetic magnets for hoisting bundled materials: When the electromagnetic magnet operates, the power supply and control equipment provide direct current to the electromagnetic magnet, which generates a strong magnetic field inside. Through the shell magnetic conductor and the working air gap, a strong magnetic force is produced in the absorbed material, thus achieving the purpose of transporting materials.

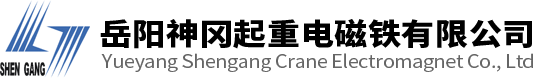

The MW12 series transport electromagnetic magnets are designed for strong magnetic circuits and can penetrate multiple layers of air gaps. They have sufficient attraction for double-layer blanks. They are suitable for hanging rods; they can also transport large steel ingots or steel balls.

Using a fully enclosed structure, with good moisture resistance; strong suction, low energy consumption, and a reasonable self-weight due to computer-optimized design, with high attraction and low energy consumption. Long lifespan, the excitation coil is treated with a special process, and the electrical and mechanical properties of the coil, as well as the heat resistance level of the insulating material, reach Class C. The duty cycle is 60%, which improves the rated duty cycle of ordinary electromagnetic magnets from the previous 50% to 60%, enhancing the efficiency of the electromagnetic magnet. High working efficiency, high-temperature lifting electromagnetic magnets use a unique insulation method, increasing the temperature of the absorbed material from the previous 600 degrees Celsius to 700 degrees Celsius, expanding the application range of the electromagnetic magnet. Easy installation, operation, and maintenance; the crane seat is easy to install, operate, and maintain.

Applications

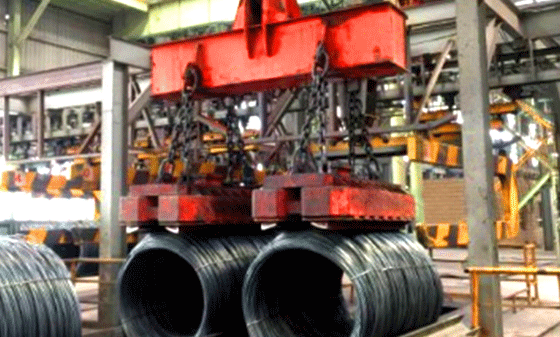

Used in industries such as metallurgy, mining, machinery, transportation, etc., for conducting materials like steel, electromagnetic robots, and other conductive materials.

Optional considerations

1) The magnetic circuit of the lifting electromagnetic magnet consists of the bell cover, inner and outer poles, iron core, and absorbed material.

2) The coil is placed in a sealed container made of the bell cover and non-magnetic protective plate, and fixed with insulating oil.

3) Overall use of welded structures.

4) The MW12 uses a double wire encapsulation structure.

5) High-temperature electromagnetic magnets use a special double radiation insulation structure.

Suitable for transporting cast iron ingots, steel balls, and various scrap steel. The method can adopt fixed voltage, strong self-method, biscuit method, etc.

Fully enclosed structure: fully enclosed structure, with good moisture resistance.

Simple operation, strong practicality.

Using a special magnetic circuit design, with high air gap magnetic density. Low self-weight and energy consumption, large crane.

Stainless steel plate, high strength, great toughness, non-magnetic induction, more impact-resistant than manufacturers using manganese plates, long-term power supply, with internal and external magnetic poles interlocking without reducing magnetic quantity.

The duty cycle is 60%, which improves the rated duty cycle of ordinary electromagnetic magnets from the previous 50% to 60%, enhancing the efficiency of the electromagnetic magnet.

Related News

The company will continue to develop and innovate with the enterprise spirit of worrying about customers first and enjoying the happiness of customers later, and strive to become a giant of modern enterprises. Welcome all friends to visit and guide our company!

Address: Liji Avenue, Junshan Industrial Park, Yueyang City, Hunan Province

Fax: 0730-8647119