The principle and Applications of electromagnetic suction cups.

2021-11-12

Abstract

The electric permanent magnetic chuck is a type of permanent magnetic chuck, named for its suction power per square centimeter being greater than that of ordinary permanent magnetic chucks. It is mainly used for clamping medium-strength grinding or milling guide workpieces, also known as magnetic chucks or permanent magnetic jacks. It is an essential handling tool in steel fields such as machinery, molds, forging, steel mills, and shipyards. Based on high-performance rare earth materials like neodymium iron boron, the chuck is manually operated by pulling the handle to rotate, thereby changing the magnetic system of the neodymium iron boron inside the chuck to hold or release the conveyed workpiece.

The electric permanent magnetic chuck has the same structure as ordinary ones, consisting of a panel, magnetic steel, base, clamping rod, and wrench. Between electric-controlled permanent magnetic chucks, the design utilizes the principles of continuous magnetic flux and magnetic field superposition, with the magnetic circuit of the permanent magnetic chuck designed as a multi-magnetic system. Through the relative motion of the magnetic system, the magnetic field strength on the working pole surface can be increased or eliminated, achieving the purpose of holding and unloading. Electric-controlled permanent magnetic chucks have strong suction, with characteristics such as high suction power, convenient operation, safe use, and energy saving.

Features of the electric permanent magnetic chuck:

1. Uses high-performance permanent magnetic material neodymium iron boron as the core of the product, making the product smaller and enhancing its lifting power.

2. The overall coefficient is 3.5 times the rated lifting power.

3. The bottom V-shaped groove design can absorb corresponding round steel and steel plates.

4. Can be used without power supply, eliminating the hassle of power.

5. Optimized magnetic circuit design, with residual magnetism almost zero.

When designing the electric permanent magnetic chuck, the magnetic circuit must be carefully designed first. A good magnetic circuit structure can gather as much magnetic flux as possible on the working surface to meet lifting requirements while using as little neodymium iron boron material as possible. At the same time, careful consideration is needed for operators to more easily unload workpieces, addressing technical difficulties such as strong suction and operational challenges. The magnetic circuit design of the electric permanent magnetic chuck has two magnetic systems, divided into active and fixed parts. Changing the state of the active magnetic system allows the working pole surface to be in a state of magnetic field superposition or to generate a reverse magnetic field, which cancels out the magnetic field.

Main applications of the electric permanent magnetic chuck

1. Metal cutting includes turning, milling, grinding, planing, drilling, etc., suitable for both ordinary machine tool applications and machining center applications, without altering the original structure of the machine tool. Due to the large market share of these devices, they have a broad market prospect.

2. Quick mold change includes injection molding machines, mold clamping machines, stamping machines, etc., saving a lot of adjustment work and achieving extremely fast mold change speeds. Injection molding machines equipped with electric permanent magnetic chucks see a significant increase in profit margins and are favored by users.

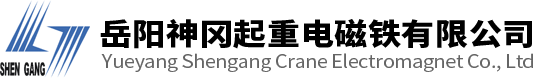

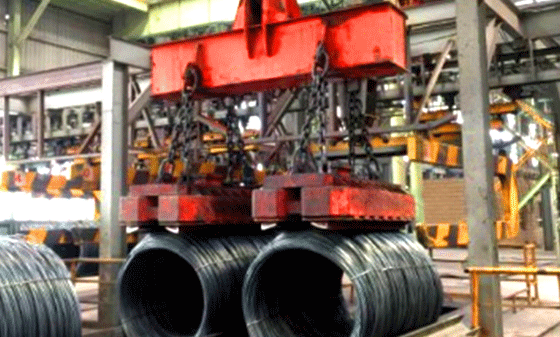

3. Lifting and handling: For the lifting of single steel plates, especially in fields such as automotive axles, automotive chassis, and container ship manufacturing, it is necessary to lift and lay steel plates flat, requiring that single steel plates be lifted without sticking. The characteristics of the electric permanent magnetic lifting system are particularly suitable for the above working conditions.

4. Welding clamping: Various pipes and steel plates need to be securely positioned with fixtures before welding. The fixtures have strong suction, reliability, and ease of operation, outperforming other types of fixtures in performance.

Related News

The company will continue to develop and innovate with the enterprise spirit of worrying about customers first and enjoying the happiness of customers later, and strive to become a giant of modern enterprises. Welcome all friends to visit and guide our company!

Address: Liji Avenue, Junshan Industrial Park, Yueyang City, Hunan Province

Fax: 0730-8647119