The function and working principle of a lifting electromagnetic suction cup

2021-11-12

Abstract

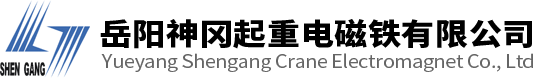

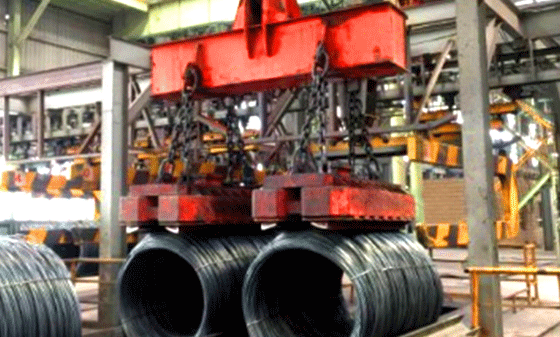

The lifting electromagnetic chuck is used to lift black metal materials and their products that have magnetic conductivity. The lifting electromagnetic chuck consists of a cast steel shell and a coil placed inside it, with direct current fed into the coil winding through a cable. When the lifting electromagnetic chuck falls on the lifted black metal product, the magnetic flux of the electromagnet is closed through the object by the electromagnet shell, generating electromagnetic suction and maintaining it until power is cut off. To ensure safety, the circuit of the lifting electromagnetic chuck has a delay performance.

Working principle of the electromagnetic chuck:

The circular electromagnetic chuck is used to lift steel ingots, cast steel parts, and scrap steel. The rectangular electromagnetic chuck is used to lift steel plates, steel pipes, and various profiles.

The advantages of the electromagnetic chuck are automatic loading and unloading and high efficiency. The disadvantages are heavy self-weight, high power consumption, and objects may fall when power is cut off. The lifting capacity is affected by temperature and the content of manganese and nickel.

Generally, for black metal products with temperatures below 200℃, the lifting capacity of the electromagnetic chuck will decrease by about 50% when the temperature reaches 500℃. When the temperature reaches 700℃, there is no lifting capacity (usually, the magnetism of carbon steel disappears at 785℃).

Currently, there are electromagnetic chucks for high-temperature lifting that can absorb high-temperature products, but ordinary electromagnetic chucks are not allowed to absorb high-temperature products.

Operational safety requirements:

① Pay attention to balance. The electromagnetic chuck should be placed above the center of gravity of the product and then powered on to prevent light iron filings from splashing;

② When lifting, the working current should reach the rated value before lifting;

③ When lowering the electromagnetic chuck, pay attention to the surrounding situation to prevent personal injury;

④ When lifting, be careful that there should be no non-magnetic objects, such as wood chips, sand, etc., between the metal products and the electromagnetic chuck, otherwise it will affect the lifting capacity;

⑤ Carefully check the components of each part, and replace them in a timely manner if damaged;

⑥ During the lifting process, special attention should be paid to safety, and it is not allowed to pass over the heads of equipment or personnel.

The previous one-

Related News

The company will continue to develop and innovate with the enterprise spirit of worrying about customers first and enjoying the happiness of customers later, and strive to become a giant of modern enterprises. Welcome all friends to visit and guide our company!

Address: Liji Avenue, Junshan Industrial Park, Yueyang City, Hunan Province

Fax: 0730-8647119