What role can a lifting electromagnetic suction cup play?

2022-01-10

Abstract

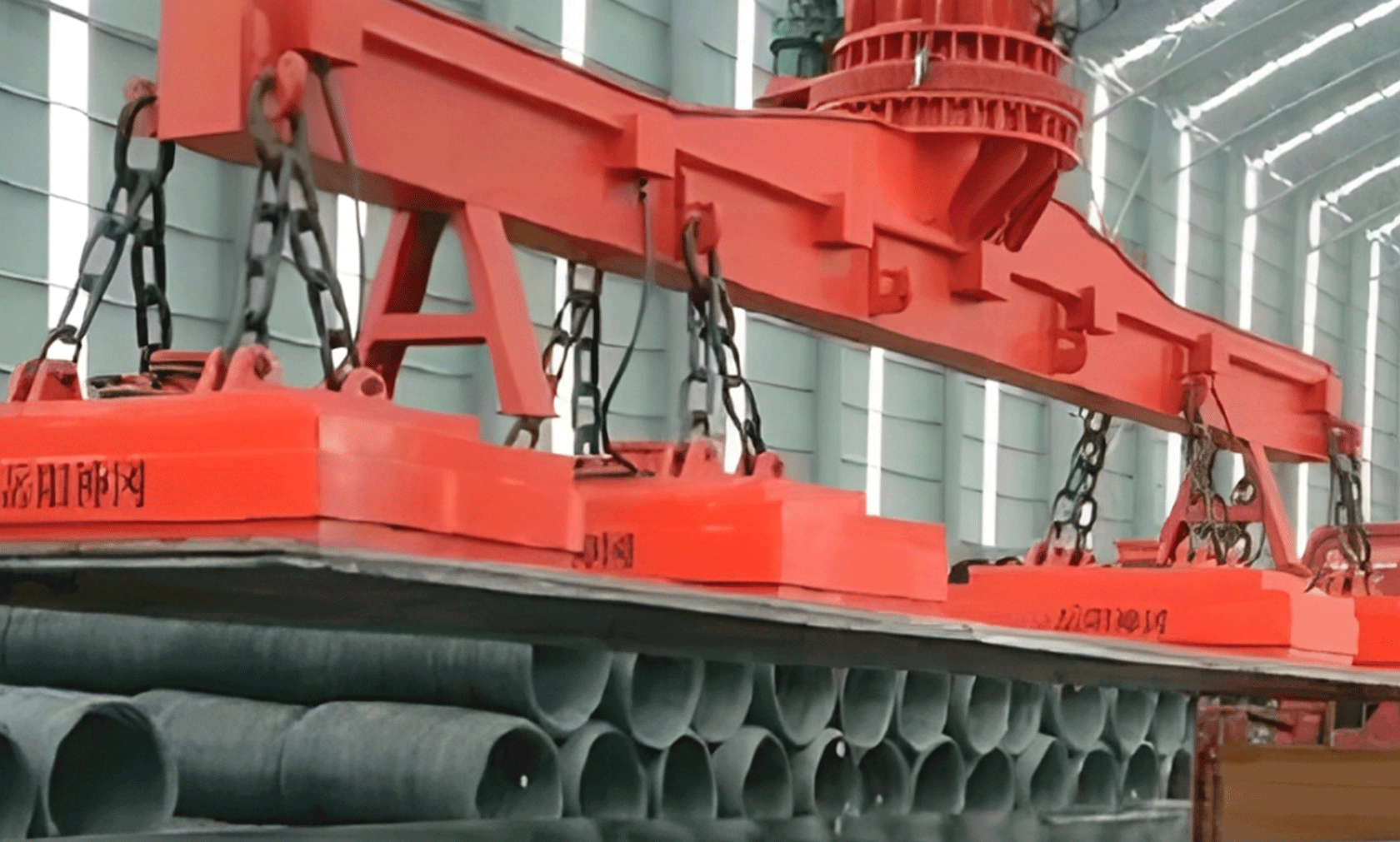

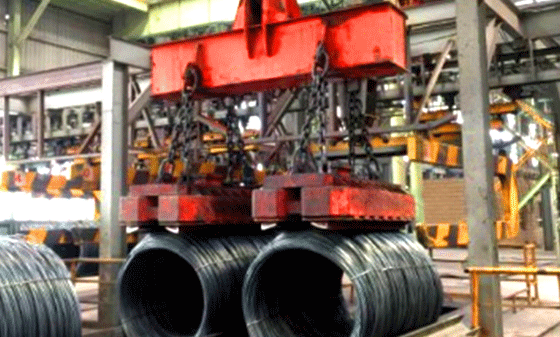

The lifting electromagnetic chuck is produced based on the principles of electromagnetism. The magnetic force is generated by exciting the internal coil, and the workpiece in contact with the surface of the panel is tightly attracted by the magnetic conductive panel. Demagnetization is achieved by turning off the coil, causing the magnetic force to disappear and the workpiece to be removed.

Applications of lifting electromagnetic chucks: workpiece fixation during the processing of iron workpieces in grinding machines, FYMC series electromagnetic tool grinders, gantry milling machines, gantry planers, etc. Advantages of lifting electromagnetic chucks:

1. Suction power of the chuck:

The electric control strong suction chuck has a strong holding force of up to 16kg/cm², with uniform and adjustable magnetic force distribution, suitable for various strong processing, rough processing, and fine processing; ordinary strong chucks have weak suction and uneven distribution, unable to meet the requirements of strong processing operations.

2. Processing accuracy:

The holding force of the electric control strong suction chuck does not need to be maintained by connecting to a power source, and continuous operation does not generate heat, thus avoiding thermal deformation of the workpiece. At the same time, even if the workpiece exceeds the workbench, the powerful and uniform disc suction can ensure high processing accuracy.

However, the magnetic force of ordinary lifting electromagnetic chucks requires a continuous supply of current, which generates heat after running for a period of time, not only causing thermal deformation of the workpiece but also reducing the magnetic force of the chuck, making it impossible to guarantee processing accuracy.

3. Performance:

The electric control strong suction chuck can be used continuously. Even if it works continuously for more than 20 hours a day, it will not fail and does not require maintenance; ordinary chucks lose suction after about six months, while lifting electromagnetic chucks can only work for a few hours a day, making the equipment prone to work and requiring frequent replacement and maintenance of internal parts.

4. Operating efficiency:

The use of ordinary strong chucks requires a lot of workpiece adjustment time, which can account for 40%-50% of the entire processing process. Clamping and positioning are prone to significant errors, resulting in a high scrap rate and extremely low efficiency; the electric control strong suction chuck has an automatic auxiliary positioning function. Just press a button to complete the clamping or release of the workpiece within 0.3 seconds, which can greatly improve production efficiency.

The harm of lifting electromagnetic chucks to the generator itself:

1. After the generator loses magnetism, the leakage magnetic field at the end of the stator increases, leading to overheating of the end components and end core.

1. After asynchronous operation, the equivalent reactance of the generator decreases. Therefore, the reactive power absorbed from the system increases, causing the stator winding to overheat.

2. The differential frequency current in the rotor winding of the generator generates additional losses in the rotor winding, causing the rotor winding to heat up.

4. For large directly cooled steam turbine generators, the average value of asynchronous torque is relatively small, and the inertia constant is also relatively low, resulting in significant asymmetry of the rotor on the vertical and horizontal axes. For these reasons, the torque and active power of the demagnetized generator will oscillate violently under heavy load. This effect is more severe for hydroelectric generators.

Related News

The company will continue to develop and innovate with the enterprise spirit of worrying about customers first and enjoying the happiness of customers later, and strive to become a giant of modern enterprises. Welcome all friends to visit and guide our company!

Address: Liji Avenue, Junshan Industrial Park, Yueyang City, Hunan Province

Fax: 0730-8647119