Products

-

-

Raw billets, beam billets, and plate billets are lifted using electric lifting magnets.

-

Specialized Lifting Electromagnet for High-Speed Wire (Coil)

-

Pipe blanks, steel pipes, large round blanks for lifting with electric lifting magnets

-

Heavy rail, steel pipe lifting with electric lifting magnets

-

Medium-thick steel plate lifting with electric lifting magnet

-

Medium-thick steel plate multi-sheet lifting special lifting electromagnet

RELATED INFORMATION

Electric Furnace Alloy Feeding Weighing and Monitoring System

Classification:

E-mail:hnyysg0730@163.com

Case Details

System Composition and Function Description

System Composition

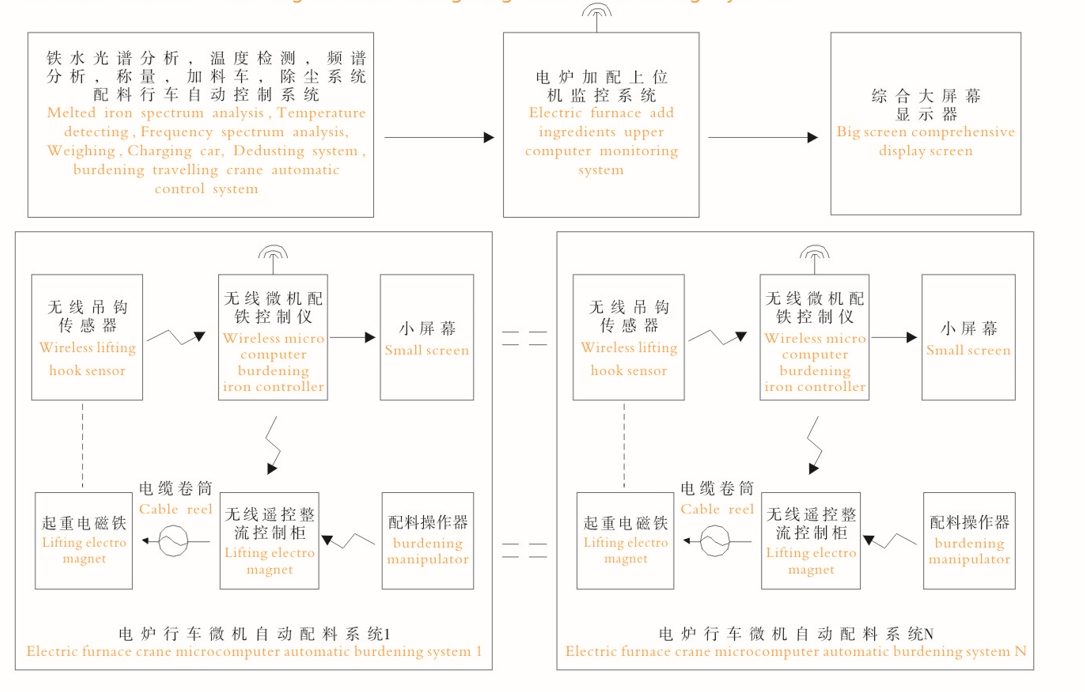

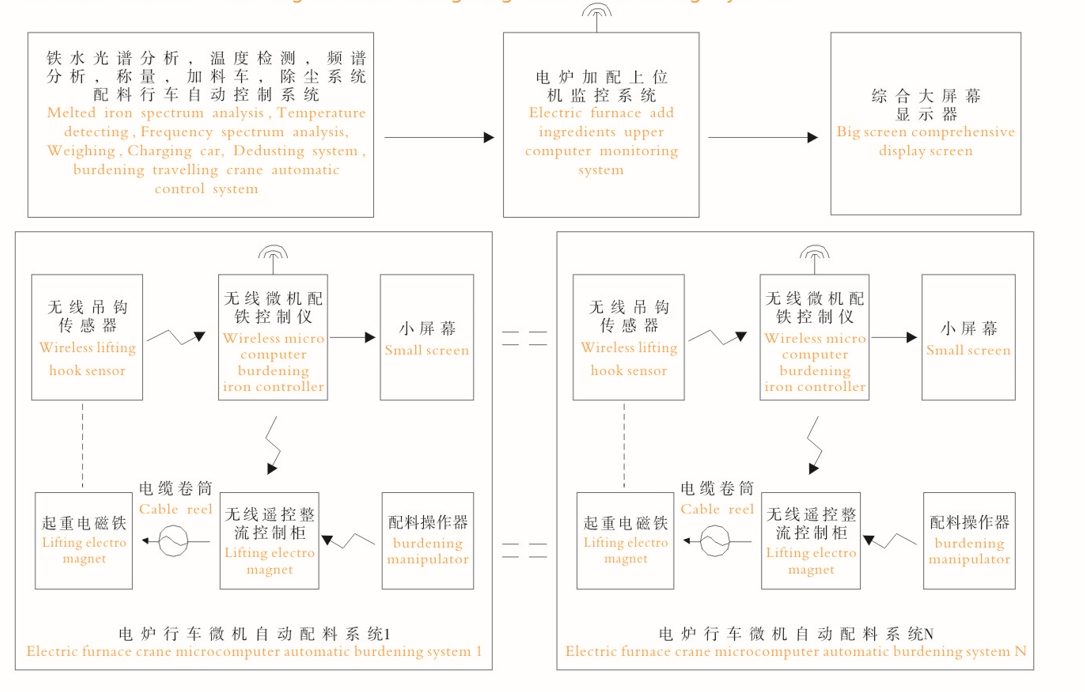

The electric furnace charging and batching weighing and monitoring system series consists of the following components: a wireless microelectromechanical electromagnetic batching system, a dust removal system for the electric furnace charging cart, and an upper-computer-based management and monitoring system for electric furnace charging and batching. Additionally, it can integrate information from the molten iron spectral analysis system, molten iron temperature detection system, alloy spectral analysis system, electric furnace molten iron weighing system, and automatic control system for the batching traveling crane, displaying all this data on a large industrial screen.

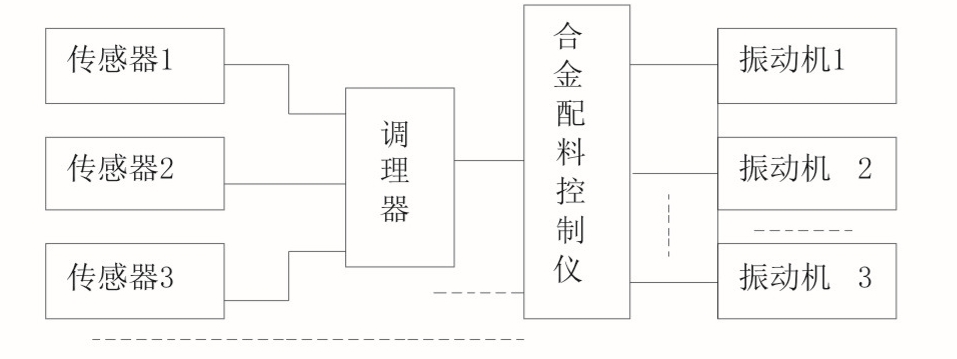

Once the system is online, it can achieve fully automated electric furnace melting, ingredient weighing, and monitoring & management. A typical, well-rounded system block diagram is shown below. Generally, customers may prefer the following components: a wireless micro-electromechanical electromagnetic batching system, high-temperature hook scales, a vibrating feeder system, a dust removal system, and a host computer-based management and monitoring system for electric furnace ingredient addition. The host computer-based management and monitoring system for electric furnace ingredient addition forms a wireless local area network together with the microcomputer-based automatic batching system for each electric furnace hoist.

I. Electromagnetic Feeding Cart System

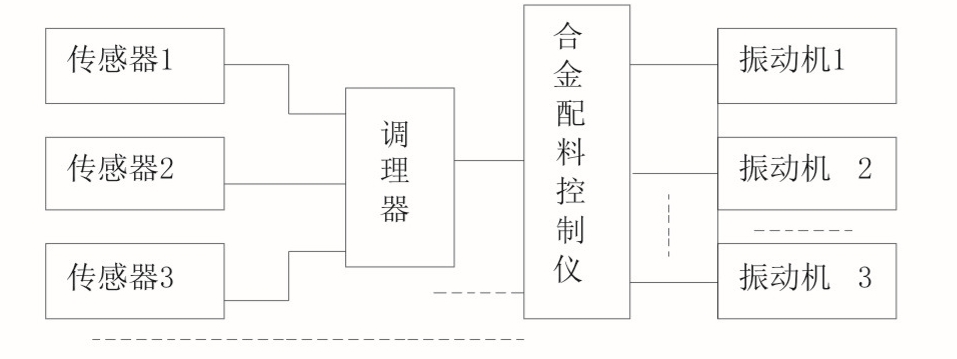

The system consists primarily of three major subsystems: the vibrating feeder system, the electromagnetic batching control and monitoring management system, and the third system.

(1) Feeding Vehicle System:

It consists of a vibrating feeder, an electrical control cabinet, and a horizontal floor-mounted cable reel.

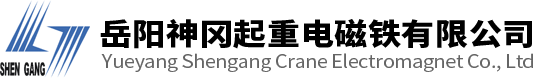

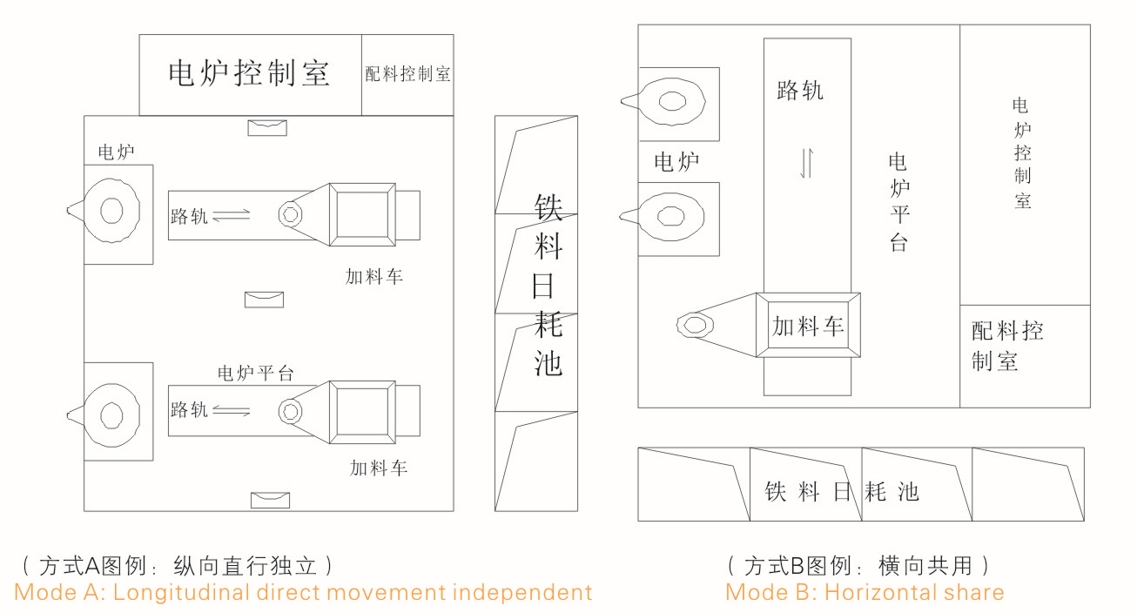

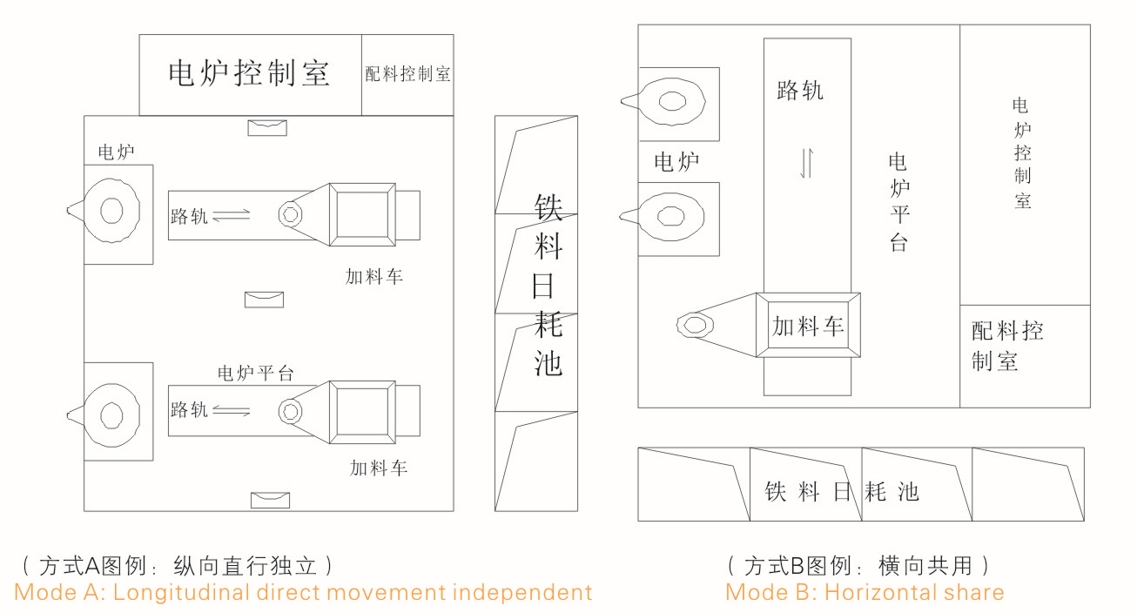

(1) Arrangement of the charging car and the electric furnace

Method A: Vertical Feed Method (ZDLC-A):

Each electric furnace is equipped with a feeding cart that moves longitudinally to deliver materials; the feeding process for each furnace is independent. The advantages include independence, reliability, and high feeding efficiency. Multiple furnaces can be operated simultaneously without interfering with each other, and they can also serve as backups for one another. The disadvantage is that the initial investment in multiple feeding carts is relatively high.

Method B: Horizontal Moving Feeding Method (ZDLC-B):

The feeding cart moves laterally, allowing it to feed two furnaces or multiple furnaces simultaneously. Using a single cart for two purposes reduces the required space by half compared to using separate carts for each furnace. However, a drawback is that if the feeding cart malfunctions, it becomes impossible to start up and feed the furnaces. Additionally, it’s necessary to ensure that the cart’s discharge port does not conflict with the position of the furnace lid.

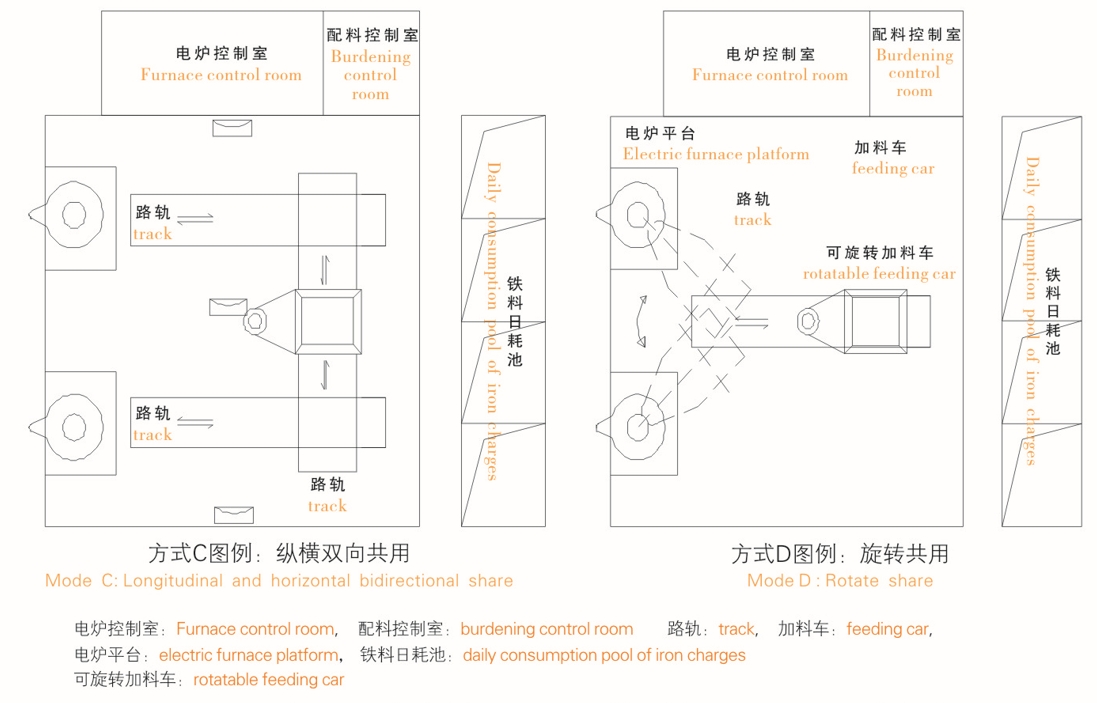

Method C Bidirectional Moving Feeding Method (ZDLC-C):

There are both longitudinal and transverse rails. The charging car can move both longitudinally and laterally, allowing it to feed materials to electric furnaces arranged side by side. Two or more electric furnaces can share a single charging car, making it versatile and cost-effective. However, the bidirectional running mechanism and the complex structure of the charging car result in higher manufacturing costs. Moreover, the longitudinal rails on the platform are higher than the platform surface, making it inconvenient to move around and more troublesome to maintain. Unless there are obstacles (such as columns) between the electric furnaces, this setup is seldom used.

Method D: Vertical Moving Rotary Feeding Method (ZDLC-D):

The feeding cart first moves longitudinally to a position midway between the two furnaces. The vibrating feeding chute on the cart is rotatable, allowing it to feed material separately to both electric furnaces. The two electric furnaces share a single feeding cart. This approach is more economical; however, the rotating mechanism of the feeding cart makes its structure complex, resulting in a relatively high failure rate and troublesome maintenance, so it is less commonly used.

(2) Precautions for the arrangement of vibrating feeders and electric furnaces:

A. Regardless of the type of charging car arrangement, it is necessary to ensure that the discharge port of the charging car does not conflict with the position of the electric furnace cover and does not interfere with the electric furnace’s environmental protection and dust removal system. These factors can also be considered comprehensively and incorporated into the integrated design.

B. When using electromagnetic disks for material feeding, the daily consumption location of iron materials should be positioned as close as possible to the waiting position of the charging car. It is essential to avoid having the electromagnetic disk lifting materials pass over the platform or the electric furnace operating area, to prevent iron materials from falling and causing injury or property damage!

C. Design Considerations:

When designing the charging cart, users must provide the relevant dimensions (A through F) as shown in Figure 1, and also specify the location of the electric furnace lid. The supporting structure of the electric furnace platform and the foundation must take into account the full-load weight of the charging cart or the full-load weight of the charging bucket, as well as the weight of the electromagnetic disc. Additionally, factors such as vibration forces, rail track positions, material bins, charging methods, conveying systems, and the overall layout of the charging cart must all be scientifically and reasonably designed.

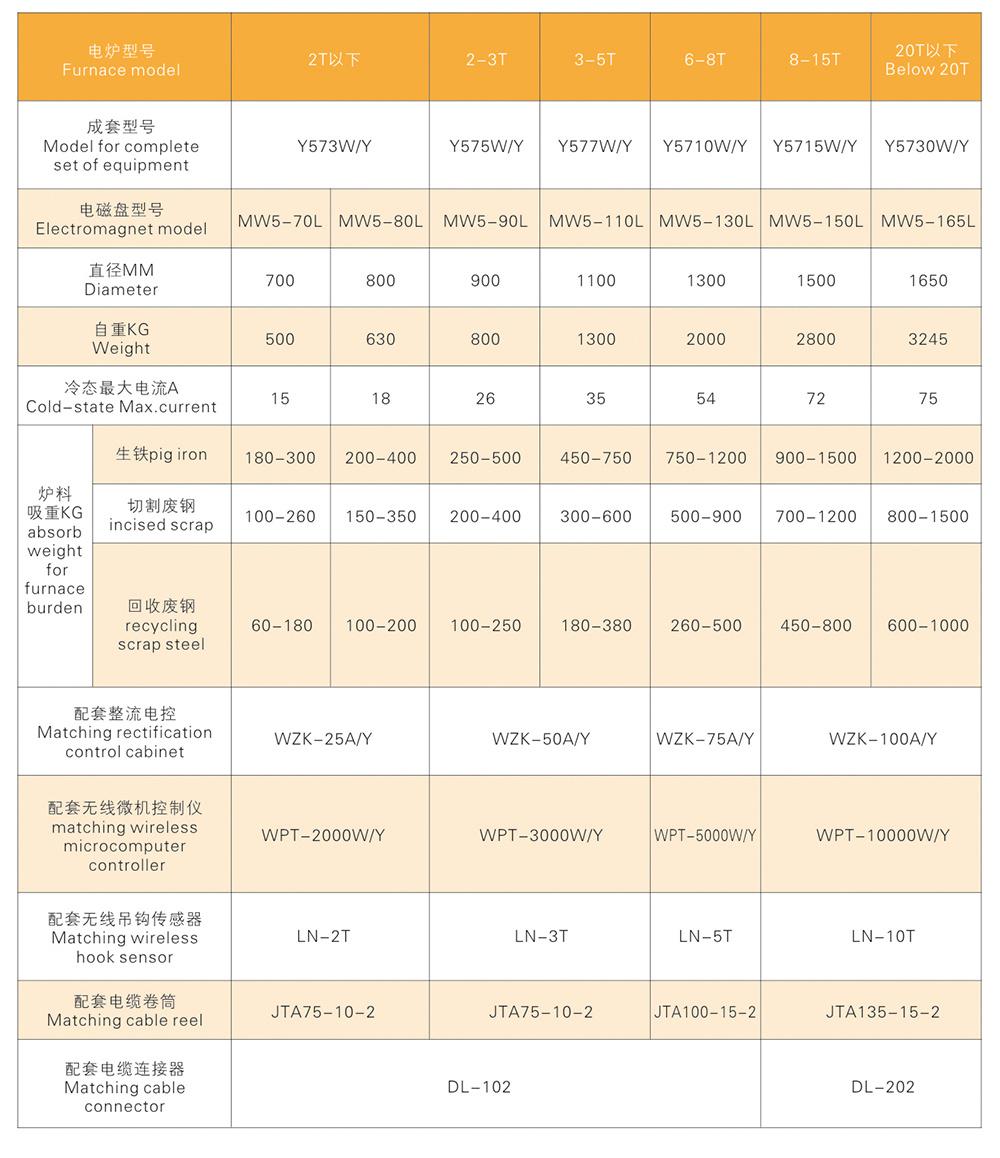

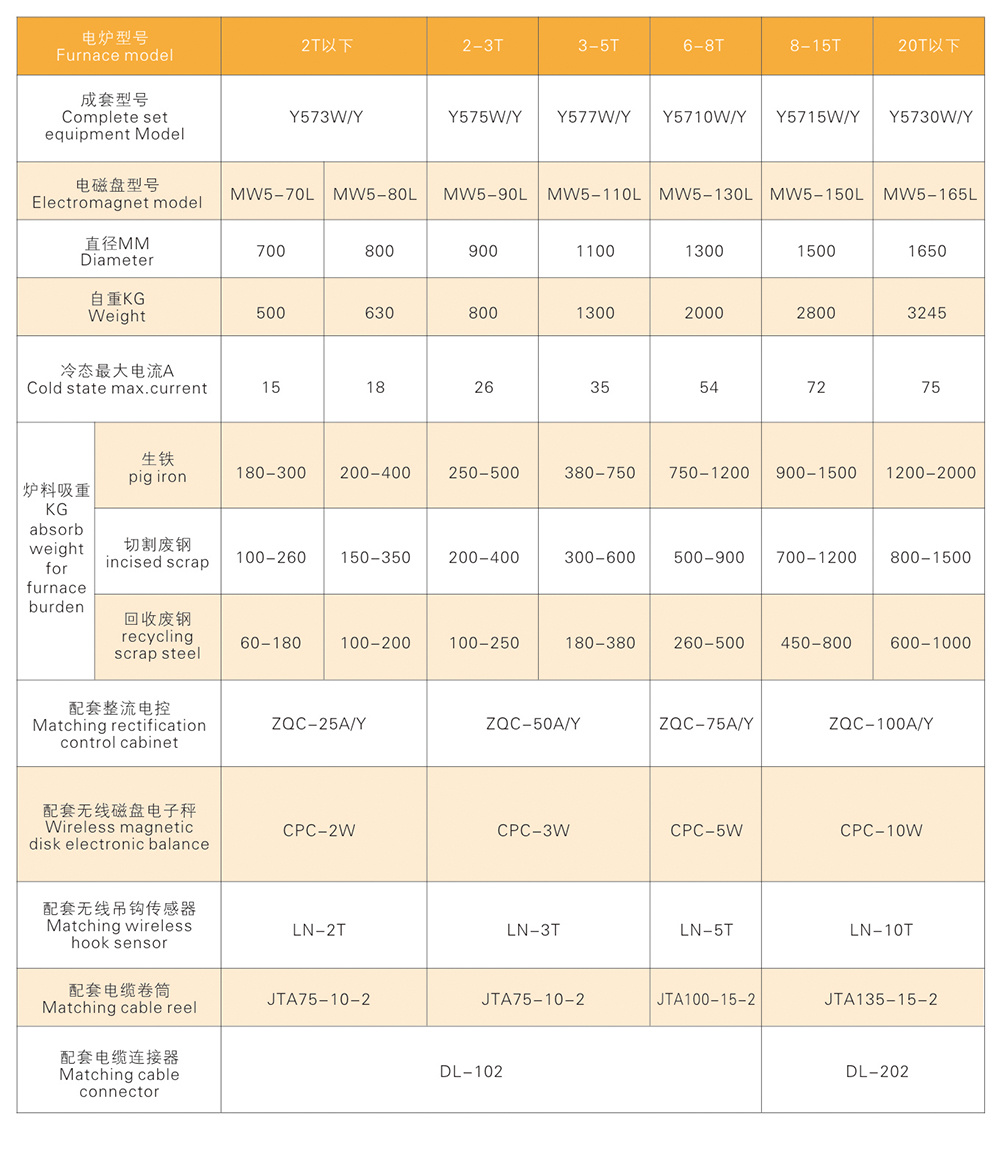

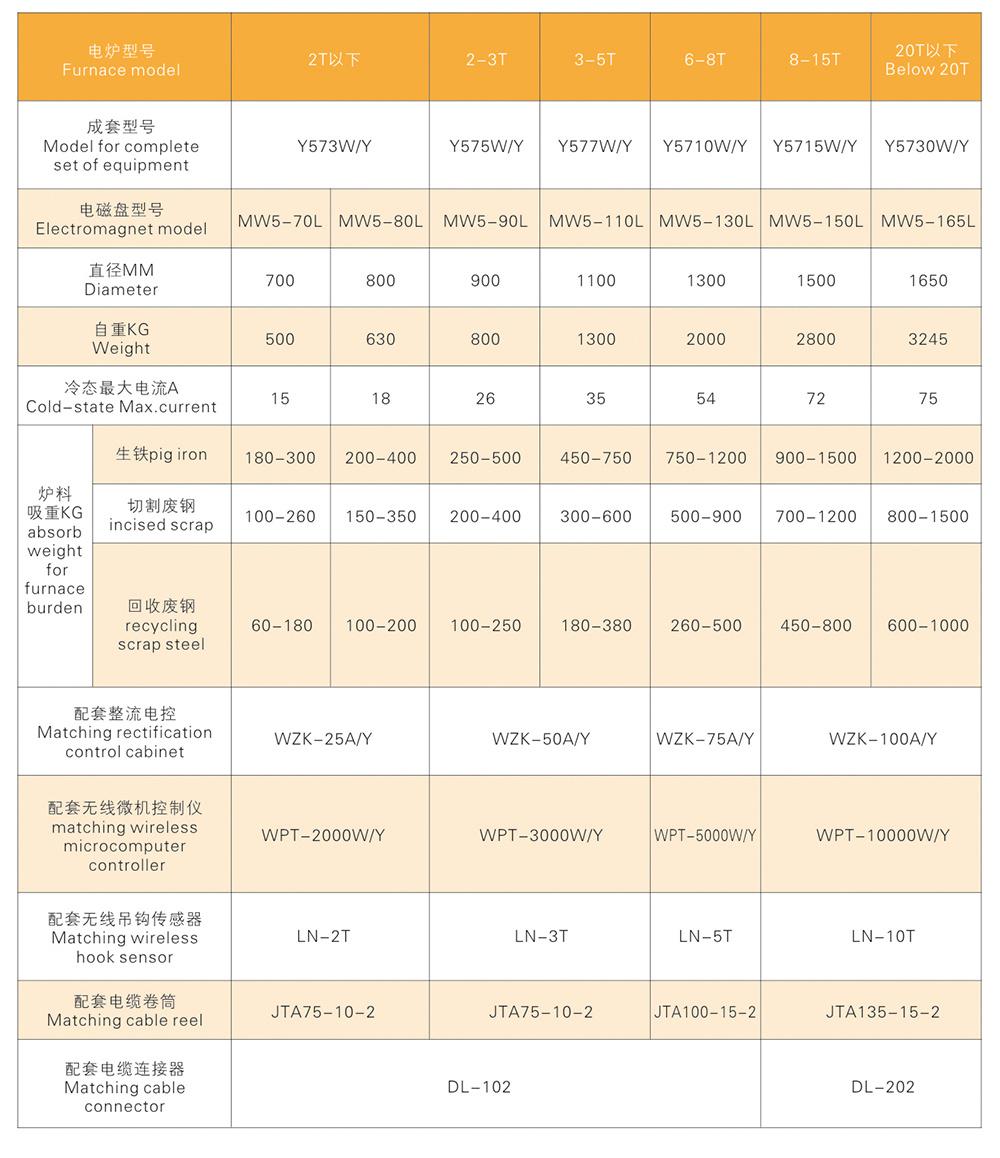

(3) Instructions for Selecting Vibratory Feeders:

a) Table (1) shows the one-to-one electric furnace charging car configuration; other one-to-two configurations can be referenced for selection. The general rule for matching electric furnaces with charging cars is: typically, each furnace is equipped with two charging units, and the charging car specifications are usually selected based on a 60% melting rate of the electric furnace. For example, a 5-ton electric furnace would ideally be paired with a 3-ton charging car. If each furnace is supplied with only one charging unit, then the charging car should have the same specification as the furnace’s melting rate—for instance, a 5-ton electric furnace would be best matched with a 5-ton charging car. Provided that the feeding and batching speed can be ensured, it is generally advisable to choose smaller-sized charging cars whenever possible. This approach not only reduces initial investment but also lowers the load-bearing requirements for the electric furnace platform, thanks to the lighter vehicle weight and reduced vibration.

b) Description of Feeding Vehicle Models: The feeding vehicle model consists of three parts: ZDLC—[space] A/B/C/D (-BP). Among these, ZDLC stands for vibrating feeding vehicle; the digit following the dash represents the rated capacity of metallic charge per vehicle (in tons); Type A indicates a longitudinal straight-forward travel mode, Type B indicates a lateral travel mode, Type C indicates a bidirectional travel mode in both longitudinal and lateral directions, and Type D indicates a straight-forward rotary travel mode. If a variable-frequency drive is used, “-BP” will be added at the end.

(4) Vibrating feeder and electrical control system specification—see below:

Feeding vehicle electrical control system:

Equipped with Siemens electrical components and comprehensive motor protection measures, the material cart ensures reliable and smooth operation. The start-and-stop operations employ regenerative braking and energy-consuming braking to guarantee smooth deceleration and stopping. Power supply and signal control cables are wound onto spring-loaded cable reels, and in some applications, a low-voltage power supply via rail tracks is also used. In certain scenarios, variable-frequency drive (VFD) control can be optionally installed, offering enhanced performance in terms of operation, feeding, and stopping when combined with VFD-driven excitation! Typically, each material cart is equipped with an electric control box that travels along with the cart; alternatively, the control box can be fixedly installed outside the cart. All material carts are fitted with mobile audio-visual warning signals to ensure both human and vehicle safety.

Centralized Feeding Control System:

Utilizing a Siemens PLC as the control core, the system can perform longitudinal (or lateral) conveying control and feed vibration for 2 to 4 material carts. It supports manual, semi-automatic, and fully automatic operation modes, features position detection and interlocking of actions, and can be linked with the electric furnace cover lifting mechanism, furnace chamber material level detection, and smoke and dust removal environmental protection equipment. All position signals are detected using Siemens-certified proximity switches.

II. Block Diagram of the Electric Furnace Charging and Weighing & Monitoring System

The electric furnace batching host computer management and monitoring wireless LAN system, the vibrating feeder system—each system’s specific configuration and model selection will be determined based on the user’s site requirements.

(1) Electric furnace with ingredient weighing system

A. System Overview

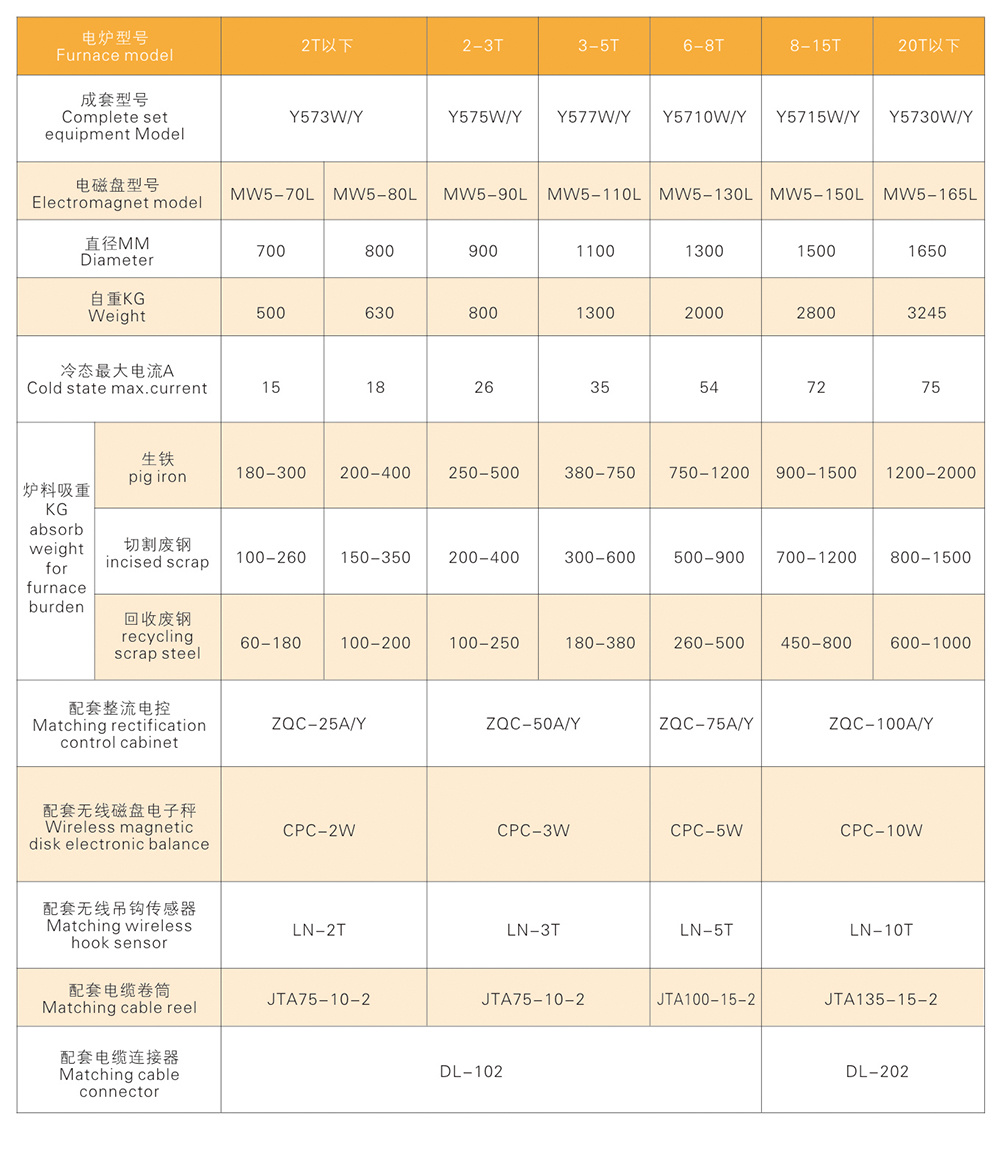

Using an electromagnetic disk to pick up materials, the microcomputer automatically controls the disk's suction force according to a pre-entered metal charge formula, precisely and automatically accumulating the ingredients. Each furnace features automatic compensation, with over-limit conditions triggering automatic alarms. The system also automatically stores and prints records of various ingredient parameters. Its static accuracy reaches as high as 1%, while its dynamic batching accuracy attains 2%. The batching speed is remarkably fast: each batch takes only 12 to 18 seconds, with each unit taking 6 to 8 minutes, and each furnace taking 12 to 16 minutes. The system can store up to 12 commonly used material recipes, and each unit (batch) can simultaneously handle up to 5 different materials (such as pig iron, returned scrap, and waste steel). It can also alternately feed 1 to 3 electric furnaces with different formulations at the same time. The system employs an industrial-grade computer control system as its core control unit, and incorporates monitoring measures such as watchdog timers and power-loss protection to ensure high system reliability. It features a standard 485/232 interface for communication with higher-level computers. The product is available in eight specifications suitable for electric furnaces ranging from 0.5T to 15T.

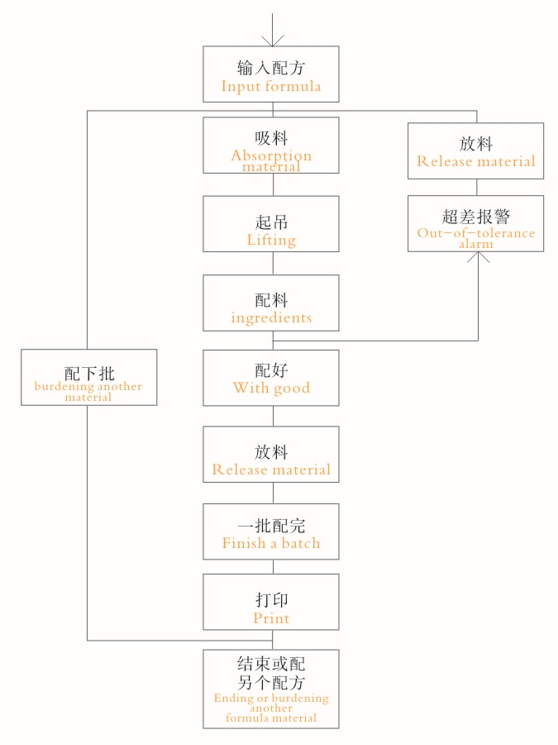

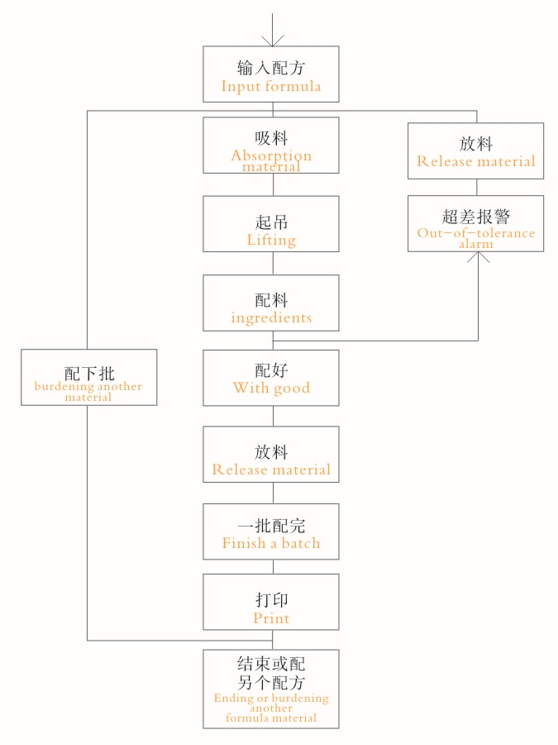

B. Microelectromechanical electromagnetic batching process:

Enter the recipe → Material suction → Lifting → Ingredient batching → Batch completed (/Over-limit alarm triggered) → Discharging material into the material cart or hopper (/Re-suction and re-batching if necessary) → Proceeding to batch the next ingredient until all batches of this type are completed → Moving on to batch the next ingredient → Repeating the process until all materials in this unit have been batched → Entering the feeding process; see the right cabinet.

A. Wireless Hook Sensor: Specially designed with shock resistance, hermetic sealing to prevent dust and water ingress, and magnetic-proof features, this sensor can withstand the frequent impacts encountered when used with electromagnetic disks for iron handling. It provides stable, wireless data transmission and is equipped with two rechargeable, sealed batteries—one in use and one as a backup (for charging). The batteries offer a runtime of 40 to 70 hours (approximately one week). The antenna is reinforced for enhanced protection, and the sensor comes with a dedicated small trolley for easy handling.

Each wireless data transmission microcomputer iron-meter set consists of two components: a wireless data-transmission hook sensor and a wireless microcomputer iron-control unit. The technical parameters and functional analysis are as follows:

1. Wireless Digital Transmission Hook-Type Weighing Sensor (LN Series)

2. Ambient-Temperature Wireless Data-Transmission Hook-Type Weighing Sensor

3. Measurement range (rated capacity): 1t, 2t, 3t, 5t, 10t

4. Characteristics:

1) Accurate measurement with adjustable display resolution as needed; accuracy class complies with international Class III weighing standards.

2) All-steel structural enclosure, impact-resistant and electromagnetic interference-proof. 3) Equipped with a weight-display circuit, featuring a 256×64 dot-matrix Chinese LCD display, unique human-machine interaction functionality, comprehensive data management and Chinese-language printing capabilities, a built-in perpetual calendar clock, an integrated signal strength and power status monitoring system, and a wireless data transmission range exceeding 100 meters in open areas without obstructions. 4) Utilizes eight frequency channels within the internationally common 433 MHz band to achieve wireless communication. 5) Employs advanced technologies such as high-speed A/D conversion, digital filtering, nonlinear compensation, and automatic zero-point tracking, enhancing the system’s anti-interference capability and accuracy while eliminating zero-point drift.

6) The sensor weighing body is powered by a large-capacity 6V/10Ah sealed lead-acid battery, with an additional backup battery that can be used alternately, allowing simultaneous operation and charging without interruption. 7) The operating temperature can be customized according to user requirements: standard type—-15~55℃; heat-resistant type—normal temperature ~180℃. 8) Equipped with RS232 [485] interface, enabling communication and networking with host computers and other devices and instruments. 9) Utilizes industrial-grade components and parts, featuring dustproof, shockproof, and mold- and corrosion-resistant designs for high reliability and durability. The product is available in four models: WPT-500W, 1000W, 2000W, and 5000W.

B. Wireless Microcomputer-Based Iron Control Unit: Features a large LCD screen with Chinese-language menu display and backlight; digital zeroing and stable-zeroing functions; fully digital calibration; batch code management; battery low-voltage indicator and alarm for the hook sensor; users can adjust the batching control parameters according to actual conditions. The wireless data transmission and remote control distance both reach up to 100 meters, with eight selectable frequency channels. It automatically and precisely accumulates batch weights, provides automatic compensation within each furnace, issues an automatic alarm when deviations exceed tolerances, and automatically stores and prints records of various batching parameters (batching time, batch number, actual weight, cumulative weight, melting rate, and melting efficiency). Static accuracy reaches as high as 0.1%, and dynamic batching accuracy reaches 2%. Batching is fast, with an average batching time of only 12–16 seconds per batch; the failure alarm rate is as low as below 5%. Each unit takes 6–8 minutes to complete batching, and each furnace takes 12–16 minutes. The system can store 8 commonly used material lists, and each unit (batch) can simultaneously handle up to 5 types of materials (such as pig iron, returned scrap, and废 steel). It can simultaneously feed 1–3 electric furnaces with different formulations in alternating cycles. The control system uses an industrial-grade computer as its core, and employs watchdog and power-loss protection measures to ensure high system reliability. It features a standard 485/232 interface for communication with a host computer, enabling two-way communication to receive recipes and transmit batching data. This batching unit is available in two models: desktop (with built-in printer) and wall-mounted (with external printer). The wall-mounted model can be installed above cranes for convenient operation.

C. Wireless remote-controlled rectifier control equipment:

The main circuit employs fully controlled intelligent power modules for power conversion, with comprehensive protection measures including high-energy varistors. A large-capacity rectifier transformer provides isolation, and the control system features a Siemens-based electronic voltage-regulating control board (with a computer interface). The batching voltage (0–400V) is continuously adjustable, and the system includes graphical indicators for each batching function.

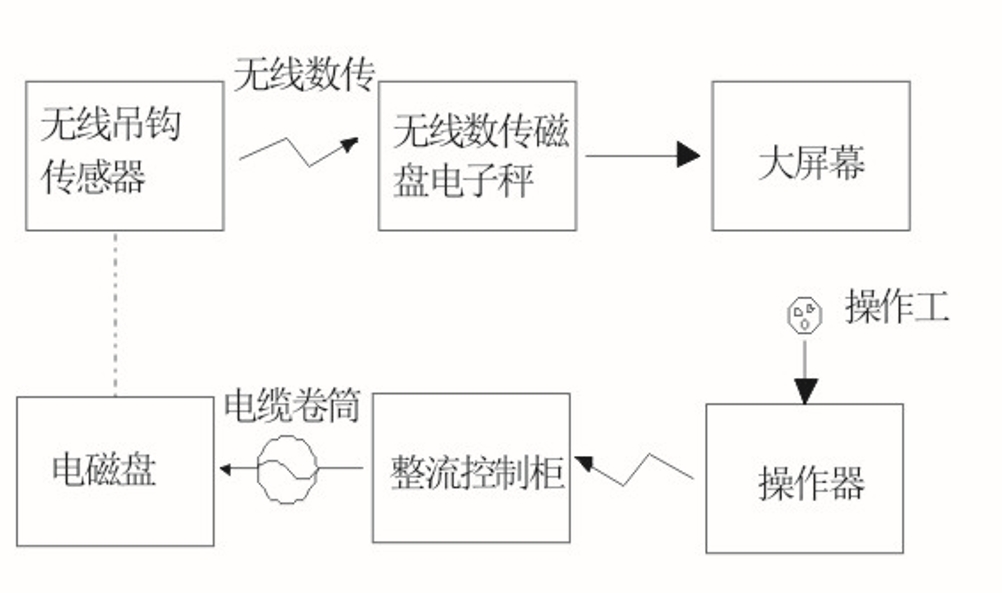

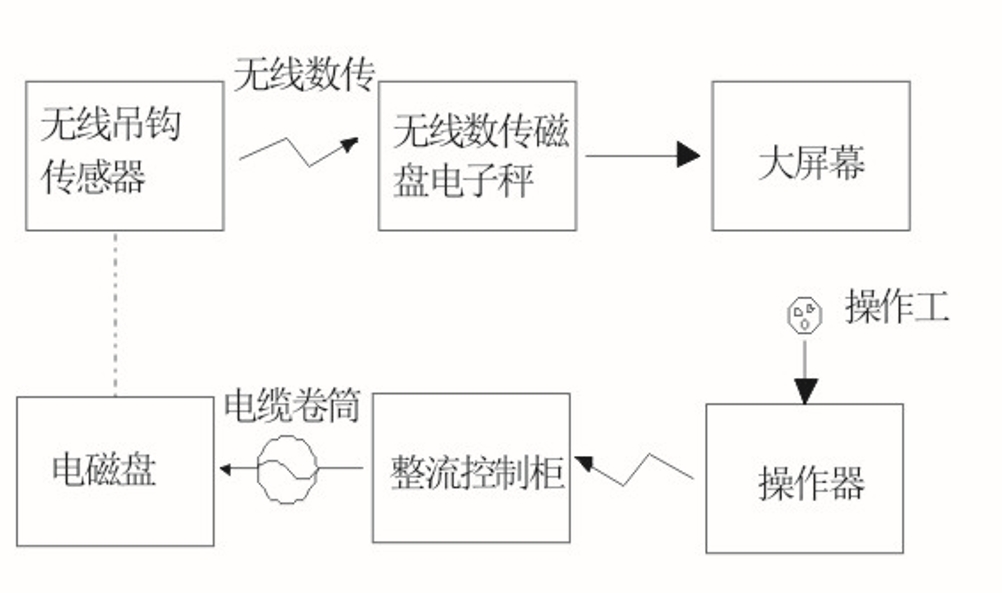

D. Digital electromagnetic batching system:

This system uses a disk-based electronic scale to display the weight of furnace charge materials, with manual magnetic adjustment for ingredient mixing. It can also print out the weights of the ingredients. Featuring high static accuracy, it is an economical choice for customers; however, due to the influence of human factors, its ingredient-mixing accuracy is relatively poor.

It comes in both wired and wireless versions. The wireless products from Kamioka Company thoroughly address the issue of frequent signal cable failures, making them an economically viable option currently available on the market!

The manual magnetic adjustment and batching process is as follows: material suction and lifting—reading the measurement—manual magnetic adjustment and batching—completing the batch—discharging the material—(printing the actual weight of this batch)—then proceeding to prepare the next batch or the next type of material—repeating this cycle endlessly.

Wireless Digital Electromagnetic Iron-Adjusting Scale (Y57AW/Y Series)—Manually adjustable magnetic iron, one set can be used with 1–2 electric furnaces.

Wireless Micro-Electromechanical Automatic Dosing System

(Y57W/series, Y-remote control)—Automatic batching; one set can be used to equip 1–2 electric furnaces.

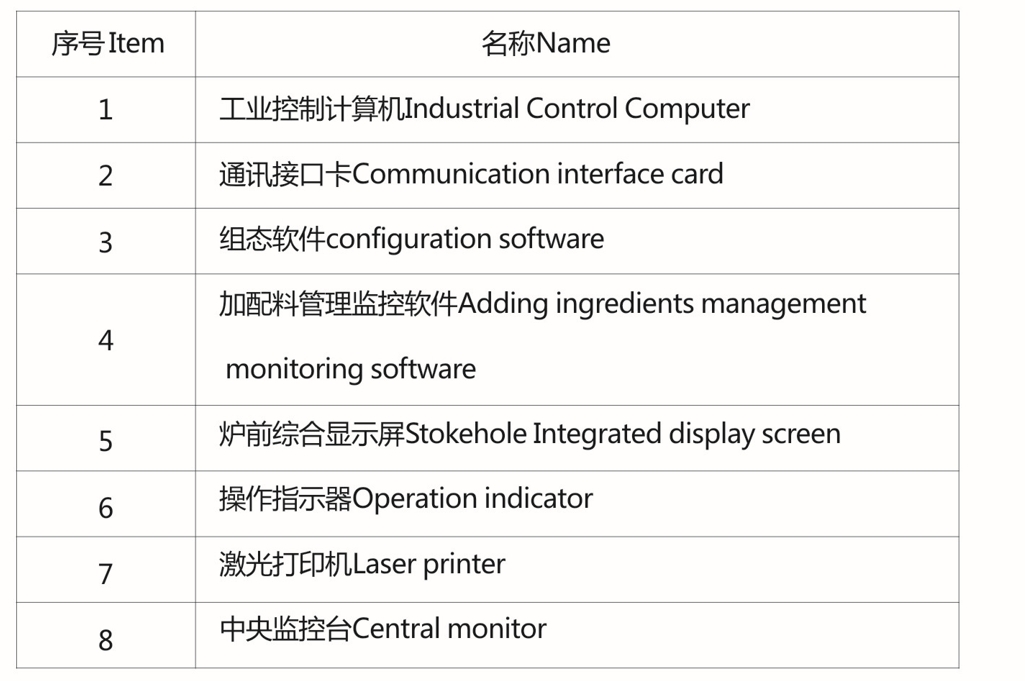

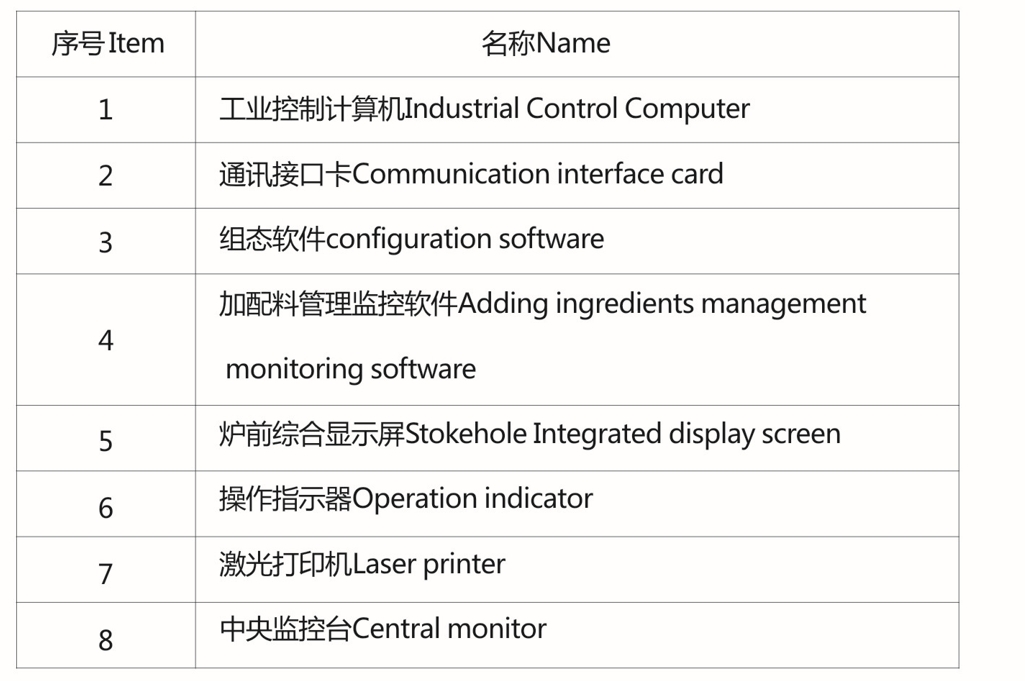

III. Monitoring and Management System

A. Monitoring and Management Software Package:

Equipped with communication capabilities to interface with various lower-level devices (including iron analyzers, alloy batching systems, spectrometers, thermal analyzers, temperature meters, large-screen displays, etc.), enabling data transmission and reception: transmitting recipe data to each batching system; managing data uploaded from various instruments and equipment; performing graphical analysis of data; printing statistical reports (by grade, daily, weekly, monthly, and annual reports, etc.); configuring and displaying the operational status of each device; setting up a main screen, a real-time monitoring screen for device operating status, a parameter-setting and modification screen, a data chart display and management screen, an alloy-batching calculation and modification screen, an alloy-addition calculation screen, a storage and printing management screen, and an expert system for electric furnace melting analysis.

B. Integrated digital display for electric furnace and ingredient addition monitoring:

A digital or dot-matrix illuminated large-screen display, installed on the exterior wall of the electric furnace platform control room, offers a clear field of vision. The large screen displays the furnace number (car number), unit number (batch number), material type code, set values for ingredients, cumulative count, actual ingredient weight, cumulative weight, status—whether the batching is complete, an alarm is triggered, or the system is in standby mode—as well as molten iron temperature and time. It can also display spectral analysis data, molten iron composition data, and molten iron temperature readings.

C. Automatic Control System for Ingredient Delivery Vehicles:

For new projects, if users so desire, automatic control of the batching crane can be considered right from the design stage. By using Siemens PLCs, the batching crane can be automatically controlled, enabling a driverless batching process. Based on the preset recipe and furnace number, the crane’s electromagnetic disk feeding device will automatically pick up the required materials from the designated daily consumption bins, perform automatic weighing according to the recipe, and then automatically load the prepared materials onto the charging car. The entire process is fully automated, truly achieving complete automation of the electric furnace charging and batching operation.

D. Electric furnace molten iron weighing system:

This includes a total weighing system for electric furnaces and a high-temperature hook scale weighing system for molten iron ladles. It can display the weighing data for each furnace’s molten iron and each ladle’s molten iron on a large-screen display, and also connect online with the host computer to upload all weighing data. This system is of great significance for metrology, raw material management, molten iron quantity control, and process management.

E. Note: Typically, 2 to 4 furnaces can share a single centralized PLC control cabinet; every two electric furnaces share a common on-site operator console. The electrical control system for the charging car can be either standard or variable-frequency drive—choose one of the two options. The external dimensions and weight of the charging car are provided for reference only and must be adjusted according to the specific conditions of each electric furnace; in particular, the length should be determined based on the distance between the center of the furnace and the edge of the furnace platform. The shape of the charging car’s discharge opening must be specified according to the dimensions of the furnace lid and the dust removal system structure.

F. Host computer monitoring, management, and display system:

Note: The ingredient management and monitoring software includes ingredient dispensing, management and monitoring functions, as well as a spectrometer, molten iron analyzer, molten iron thermometer, electric furnace weighing system, and online weight management for steel ladle carts. Additionally, an automatic control system for the feeding crane will be quoted separately upon customer request.

IV. Product Illustrations of the Electric Furnace Charging System:

System Composition and Function Description

System Composition

The electric furnace charging and batching weighing and monitoring system series consists of the following components: a wireless microelectromechanical electromagnetic batching system, a dust removal system for the electric furnace charging cart, and an upper-computer-based management and monitoring system for electric furnace charging and batching. Additionally, it can integrate information from the molten iron spectral analysis system, molten iron temperature detection system, alloy spectral analysis system, electric furnace molten iron weighing system, and automatic control system for the batching traveling crane, displaying all this data on a large industrial screen.

Once the system is online, it can achieve fully automated electric furnace melting, ingredient weighing, and monitoring & management. A typical, well-rounded system block diagram is shown below. Generally, customers may prefer the following components: a wireless micro-electromechanical electromagnetic batching system, high-temperature hook scales, a vibrating feeder system, a dust removal system, and a host computer-based management and monitoring system for electric furnace ingredient addition. The host computer-based management and monitoring system for electric furnace ingredient addition forms a wireless local area network together with the microcomputer-based automatic batching system for each electric furnace hoist.

I. Electromagnetic Feeding Cart System

The system consists primarily of three major subsystems: the vibrating feeder system, the electromagnetic batching control and monitoring management system, and the third system.

(1) Feeding Vehicle System:

It consists of a vibrating feeder, an electrical control cabinet, and a horizontal floor-mounted cable reel.

(1) Arrangement of the charging car and the electric furnace

Method A: Vertical Feed Method (ZDLC-A):

Each electric furnace is equipped with a feeding cart that moves longitudinally to deliver materials; the feeding process for each furnace is independent. The advantages include independence, reliability, and high feeding efficiency. Multiple furnaces can be operated simultaneously without interfering with each other, and they can also serve as backups for one another. The disadvantage is that the initial investment in multiple feeding carts is relatively high.

Method B: Horizontal Moving Feeding Method (ZDLC-B):

The feeding cart moves laterally, allowing it to feed two furnaces or multiple furnaces simultaneously. Using a single cart for two purposes reduces the required space by half compared to using separate carts for each furnace. However, a drawback is that if the feeding cart malfunctions, it becomes impossible to start up and feed the furnaces. Additionally, it’s necessary to ensure that the cart’s discharge port does not conflict with the position of the furnace lid.

Method C Bidirectional Moving Feeding Method (ZDLC-C):

There are both longitudinal and transverse rails. The charging car can move both longitudinally and laterally, allowing it to feed materials to electric furnaces arranged side by side. Two or more electric furnaces can share a single charging car, making it versatile and cost-effective. However, the bidirectional running mechanism and the complex structure of the charging car result in higher manufacturing costs. Moreover, the longitudinal rails on the platform are higher than the platform surface, making it inconvenient to move around and more troublesome to maintain. Unless there are obstacles (such as columns) between the electric furnaces, this setup is seldom used.

Method D: Vertical Moving Rotary Feeding Method (ZDLC-D):

The feeding cart first moves longitudinally to a position midway between the two furnaces. The vibrating feeding chute on the cart is rotatable, allowing it to feed material separately to both electric furnaces. The two electric furnaces share a single feeding cart. This approach is more economical; however, the rotating mechanism of the feeding cart makes its structure complex, resulting in a relatively high failure rate and troublesome maintenance, so it is less commonly used.

(2) Precautions for the arrangement of vibrating feeders and electric furnaces:

A. Regardless of the type of charging car arrangement, it is necessary to ensure that the discharge port of the charging car does not conflict with the position of the electric furnace cover and does not interfere with the electric furnace’s environmental protection and dust removal system. These factors can also be considered comprehensively and incorporated into the integrated design.

B. When using electromagnetic disks for material feeding, the daily consumption location of iron materials should be positioned as close as possible to the waiting position of the charging car. It is essential to avoid having the electromagnetic disk lifting materials pass over the platform or the electric furnace operating area, to prevent iron materials from falling and causing injury or property damage!

C. Design Considerations:

When designing the charging cart, users must provide the relevant dimensions (A through F) as shown in Figure 1, and also specify the location of the electric furnace lid. The supporting structure of the electric furnace platform and the foundation must take into account the full-load weight of the charging cart or the full-load weight of the charging bucket, as well as the weight of the electromagnetic disc. Additionally, factors such as vibration forces, rail track positions, material bins, charging methods, conveying systems, and the overall layout of the charging cart must all be scientifically and reasonably designed.

(3) Instructions for Selecting Vibratory Feeders:

a) Table (1) shows the one-to-one electric furnace charging car configuration; other one-to-two configurations can be referenced for selection. The general rule for matching electric furnaces with charging cars is: typically, each furnace is equipped with two charging units, and the charging car specifications are usually selected based on a 60% melting rate of the electric furnace. For example, a 5-ton electric furnace would ideally be paired with a 3-ton charging car. If each furnace is supplied with only one charging unit, then the charging car should have the same specification as the furnace’s melting rate—for instance, a 5-ton electric furnace would be best matched with a 5-ton charging car. Provided that the feeding and batching speed can be ensured, it is generally advisable to choose smaller-sized charging cars whenever possible. This approach not only reduces initial investment but also lowers the load-bearing requirements for the electric furnace platform, thanks to the lighter vehicle weight and reduced vibration.

b) Description of Feeding Vehicle Models: The feeding vehicle model consists of three parts: ZDLC—[space] A/B/C/D (-BP). Among these, ZDLC stands for vibrating feeding vehicle; the digit following the dash represents the rated capacity of metallic charge per vehicle (in tons); Type A indicates a longitudinal straight-forward travel mode, Type B indicates a lateral travel mode, Type C indicates a bidirectional travel mode in both longitudinal and lateral directions, and Type D indicates a straight-forward rotary travel mode. If a variable-frequency drive is used, “-BP” will be added at the end.

(4) Vibrating feeder and electrical control system specification—see below:

Feeding vehicle electrical control system:

Equipped with Siemens electrical components and comprehensive motor protection measures, the material cart ensures reliable and smooth operation. The start-and-stop operations employ regenerative braking and energy-consuming braking to guarantee smooth deceleration and stopping. Power supply and signal control cables are wound onto spring-loaded cable reels, and in some applications, a low-voltage power supply via rail tracks is also used. In certain scenarios, variable-frequency drive (VFD) control can be optionally installed, offering enhanced performance in terms of operation, feeding, and stopping when combined with VFD-driven excitation! Typically, each material cart is equipped with an electric control box that travels along with the cart; alternatively, the control box can be fixedly installed outside the cart. All material carts are fitted with mobile audio-visual warning signals to ensure both human and vehicle safety.

Centralized Feeding Control System:

Utilizing a Siemens PLC as the control core, the system can perform longitudinal (or lateral) conveying control and feed vibration for 2 to 4 material carts. It supports manual, semi-automatic, and fully automatic operation modes, features position detection and interlocking of actions, and can be linked with the electric furnace cover lifting mechanism, furnace chamber material level detection, and smoke and dust removal environmental protection equipment. All position signals are detected using Siemens-certified proximity switches.

II. Block Diagram of the Electric Furnace Charging and Weighing & Monitoring System

The electric furnace batching host computer management and monitoring wireless LAN system, the vibrating feeder system—each system’s specific configuration and model selection will be determined based on the user’s site requirements.

(1) Electric furnace with ingredient weighing system

A. System Overview

Using an electromagnetic disk to pick up materials, the microcomputer automatically controls the disk's suction force according to a pre-entered metal charge formula, precisely and automatically accumulating the ingredients. Each furnace features automatic compensation, with over-limit conditions triggering automatic alarms. The system also automatically stores and prints records of various ingredient parameters. Its static accuracy reaches as high as 1%, while its dynamic batching accuracy attains 2%. The batching speed is remarkably fast: each batch takes only 12 to 18 seconds, with each unit taking 6 to 8 minutes, and each furnace taking 12 to 16 minutes. The system can store up to 12 commonly used material recipes, and each unit (batch) can simultaneously handle up to 5 different materials (such as pig iron, returned scrap, and waste steel). It can also alternately feed 1 to 3 electric furnaces with different formulations at the same time. The system employs an industrial-grade computer control system as its core control unit, and incorporates monitoring measures such as watchdog timers and power-loss protection to ensure high system reliability. It features a standard 485/232 interface for communication with higher-level computers. The product is available in eight specifications suitable for electric furnaces ranging from 0.5T to 15T.

B. Microelectromechanical electromagnetic batching process:

Enter the recipe → Material suction → Lifting → Ingredient batching → Batch completed (/Over-limit alarm triggered) → Discharging material into the material cart or hopper (/Re-suction and re-batching if necessary) → Proceeding to batch the next ingredient until all batches of this type are completed → Moving on to batch the next ingredient → Repeating the process until all materials in this unit have been batched → Entering the feeding process; see the right cabinet.

A. Wireless Hook Sensor: Specially designed with shock resistance, hermetic sealing to prevent dust and water ingress, and magnetic-proof features, this sensor can withstand the frequent impacts encountered when used with electromagnetic disks for iron handling. It provides stable, wireless data transmission and is equipped with two rechargeable, sealed batteries—one in use and one as a backup (for charging). The batteries offer a runtime of 40 to 70 hours (approximately one week). The antenna is reinforced for enhanced protection, and the sensor comes with a dedicated small trolley for easy handling.

Each wireless data transmission microcomputer iron-meter set consists of two components: a wireless data-transmission hook sensor and a wireless microcomputer iron-control unit. The technical parameters and functional analysis are as follows:

1. Wireless Digital Transmission Hook-Type Weighing Sensor (LN Series)

2. Ambient-Temperature Wireless Data-Transmission Hook-Type Weighing Sensor

3. Measurement range (rated capacity): 1t, 2t, 3t, 5t, 10t

4. Characteristics:

1) Accurate measurement with adjustable display resolution as needed; accuracy class complies with international Class III weighing standards.

2) All-steel structural enclosure, impact-resistant and electromagnetic interference-proof. 3) Equipped with a weight-display circuit, featuring a 256×64 dot-matrix Chinese LCD display, unique human-machine interaction functionality, comprehensive data management and Chinese-language printing capabilities, a built-in perpetual calendar clock, an integrated signal strength and power status monitoring system, and a wireless data transmission range exceeding 100 meters in open areas without obstructions. 4) Utilizes eight frequency channels within the internationally common 433 MHz band to achieve wireless communication. 5) Employs advanced technologies such as high-speed A/D conversion, digital filtering, nonlinear compensation, and automatic zero-point tracking, enhancing the system’s anti-interference capability and accuracy while eliminating zero-point drift.

6) The sensor weighing body is powered by a large-capacity 6V/10Ah sealed lead-acid battery, with an additional backup battery that can be used alternately, allowing simultaneous operation and charging without interruption. 7) The operating temperature can be customized according to user requirements: standard type—-15~55℃; heat-resistant type—normal temperature ~180℃. 8) Equipped with RS232 [485] interface, enabling communication and networking with host computers and other devices and instruments. 9) Utilizes industrial-grade components and parts, featuring dustproof, shockproof, and mold- and corrosion-resistant designs for high reliability and durability. The product is available in four models: WPT-500W, 1000W, 2000W, and 5000W.

B. Wireless Microcomputer-Based Iron Control Unit: Features a large LCD screen with Chinese-language menu display and backlight; digital zeroing and stable-zeroing functions; fully digital calibration; batch code management; battery low-voltage indicator and alarm for the hook sensor; users can adjust the batching control parameters according to actual conditions. The wireless data transmission and remote control distance both reach up to 100 meters, with eight selectable frequency channels. It automatically and precisely accumulates batch weights, provides automatic compensation within each furnace, issues an automatic alarm when deviations exceed tolerances, and automatically stores and prints records of various batching parameters (batching time, batch number, actual weight, cumulative weight, melting rate, and melting efficiency). Static accuracy reaches as high as 0.1%, and dynamic batching accuracy reaches 2%. Batching is fast, with an average batching time of only 12–16 seconds per batch; the failure alarm rate is as low as below 5%. Each unit takes 6–8 minutes to complete batching, and each furnace takes 12–16 minutes. The system can store 8 commonly used material lists, and each unit (batch) can simultaneously handle up to 5 types of materials (such as pig iron, returned scrap, and废 steel). It can simultaneously feed 1–3 electric furnaces with different formulations in alternating cycles. The control system uses an industrial-grade computer as its core, and employs watchdog and power-loss protection measures to ensure high system reliability. It features a standard 485/232 interface for communication with a host computer, enabling two-way communication to receive recipes and transmit batching data. This batching unit is available in two models: desktop (with built-in printer) and wall-mounted (with external printer). The wall-mounted model can be installed above cranes for convenient operation.

C. Wireless remote-controlled rectifier control equipment:

The main circuit employs fully controlled intelligent power modules for power conversion, with comprehensive protection measures including high-energy varistors. A large-capacity rectifier transformer provides isolation, and the control system features a Siemens-based electronic voltage-regulating control board (with a computer interface). The batching voltage (0–400V) is continuously adjustable, and the system includes graphical indicators for each batching function.

D. Digital electromagnetic batching system:

This system uses a disk-based electronic scale to display the weight of furnace charge materials, with manual magnetic adjustment for ingredient mixing. It can also print out the weights of the ingredients. Featuring high static accuracy, it is an economical choice for customers; however, due to the influence of human factors, its ingredient-mixing accuracy is relatively poor.

It comes in both wired and wireless versions. The wireless products from Kamioka Company thoroughly address the issue of frequent signal cable failures, making them an economically viable option currently available on the market!

The manual magnetic adjustment and batching process is as follows: material suction and lifting—reading the measurement—manual magnetic adjustment and batching—completing the batch—discharging the material—(printing the actual weight of this batch)—then proceeding to prepare the next batch or the next type of material—repeating this cycle endlessly.

Wireless Digital Electromagnetic Iron-Adjusting Scale (Y57AW/Y Series)—Manually adjustable magnetic iron, one set can be used with 1–2 electric furnaces.

Wireless Micro-Electromechanical Automatic Dosing System

(Y57W/series, Y-remote control)—Automatic batching; one set can be used to equip 1–2 electric furnaces.

III. Monitoring and Management System

A. Monitoring and Management Software Package:

Equipped with communication capabilities to interface with various lower-level devices (including iron analyzers, alloy batching systems, spectrometers, thermal analyzers, temperature meters, large-screen displays, etc.), enabling data transmission and reception: transmitting recipe data to each batching system; managing data uploaded from various instruments and equipment; performing graphical analysis of data; printing statistical reports (by grade, daily, weekly, monthly, and annual reports, etc.); configuring and displaying the operational status of each device; setting up a main screen, a real-time monitoring screen for device operating status, a parameter-setting and modification screen, a data chart display and management screen, an alloy-batching calculation and modification screen, an alloy-addition calculation screen, a storage and printing management screen, and an expert system for electric furnace melting analysis.

B. Integrated digital display for electric furnace and ingredient addition monitoring:

A digital or dot-matrix illuminated large-screen display, installed on the exterior wall of the electric furnace platform control room, offers a clear field of vision. The large screen displays the furnace number (car number), unit number (batch number), material type code, set values for ingredients, cumulative count, actual ingredient weight, cumulative weight, status—whether the batching is complete, an alarm is triggered, or the system is in standby mode—as well as molten iron temperature and time. It can also display spectral analysis data, molten iron composition data, and molten iron temperature readings.

C. Automatic Control System for Ingredient Delivery Vehicles:

For new projects, if users so desire, automatic control of the batching crane can be considered right from the design stage. By using Siemens PLCs, the batching crane can be automatically controlled, enabling a driverless batching process. Based on the preset recipe and furnace number, the crane’s electromagnetic disk feeding device will automatically pick up the required materials from the designated daily consumption bins, perform automatic weighing according to the recipe, and then automatically load the prepared materials onto the charging car. The entire process is fully automated, truly achieving complete automation of the electric furnace charging and batching operation.

D. Electric furnace molten iron weighing system:

This includes a total weighing system for electric furnaces and a high-temperature hook scale weighing system for molten iron ladles. It can display the weighing data for each furnace’s molten iron and each ladle’s molten iron on a large-screen display, and also connect online with the host computer to upload all weighing data. This system is of great significance for metrology, raw material management, molten iron quantity control, and process management.

E. Note: Typically, 2 to 4 furnaces can share a single centralized PLC control cabinet; every two electric furnaces share a common on-site operator console. The electrical control system for the charging car can be either standard or variable-frequency drive—choose one of the two options. The external dimensions and weight of the charging car are provided for reference only and must be adjusted according to the specific conditions of each electric furnace; in particular, the length should be determined based on the distance between the center of the furnace and the edge of the furnace platform. The shape of the charging car’s discharge opening must be specified according to the dimensions of the furnace lid and the dust removal system structure.

F. Host computer monitoring, management, and display system:

Note: The ingredient management and monitoring software includes ingredient dispensing, management and monitoring functions, as well as a spectrometer, molten iron analyzer, molten iron thermometer, electric furnace weighing system, and online weight management for steel ladle carts. Additionally, an automatic control system for the feeding crane will be quoted separately upon customer request.

IV. Product Illustrations of the Electric Furnace Charging System:

Key words:

Electromagnetic equipment manufacturing, multi-function lifting electromagnet, special lifting electromagnet, multi-purpose lifting electromagnet, permanent magnet coupling hysteresis head

Previous Page

Next Page

RELATED PRODUCTS

This series is designed for lifting and handling cast iron ingots, steel balls, pig iron blocks, machined chips; return materials, iron concentrate powder, cut-off ends; packaged scrap steel, and more. The excitation methods available include: rated voltage DC 220V mode; and strong excitation mode—over-excitation mode.

This series features oval-shaped lifting electromagnets, primarily used for efficiently loading and unloading scrap steel in narrow vehicle compartments. Customization is available based on the specific dimensions of the vehicle compartment.

This series features the most widely used rectangular electromagnets, primarily suited for lifting billets, ingots, and large initial rolling billets. They can also be used for lifting round billets and structural steel. Different magnetic circuit designs are employed to accommodate various types of steel.

Online consultation

The company will continue to develop and innovate with the enterprise spirit of worrying about customers first and enjoying the happiness of customers later, and strive to become a giant of modern enterprises. Welcome all friends to visit and guide our company!

Address: Liji Avenue, Junshan Industrial Park, Yueyang City, Hunan Province

Fax: 0730-8647119