Products

-

-

Raw billets, beam billets, and plate billets are lifted using electric lifting magnets.

-

Specialized Lifting Electromagnet for High-Speed Wire (Coil)

-

Pipe blanks, steel pipes, large round blanks for lifting with electric lifting magnets

-

Heavy rail, steel pipe lifting with electric lifting magnets

-

Medium-thick steel plate lifting with electric lifting magnet

-

Medium-thick steel plate multi-sheet lifting special lifting electromagnet

RELATED INFORMATION

VT-STQOL Non-Contact Digital Control Rectifier Control Device

Classification:

E-mail:hnyysg0730@163.com

Case Details

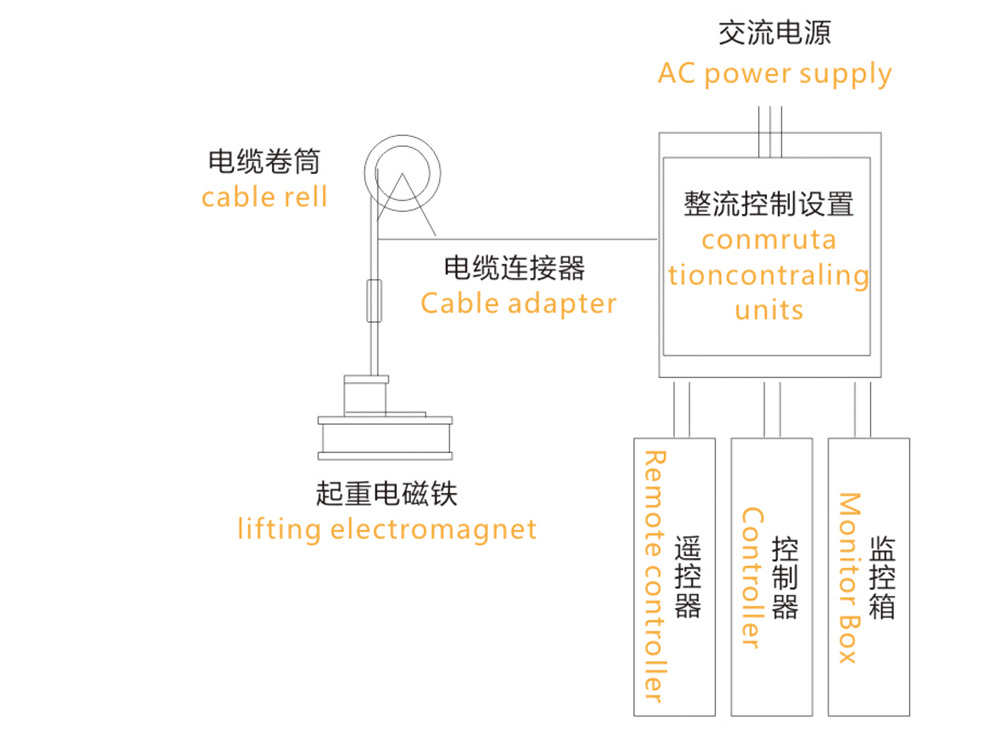

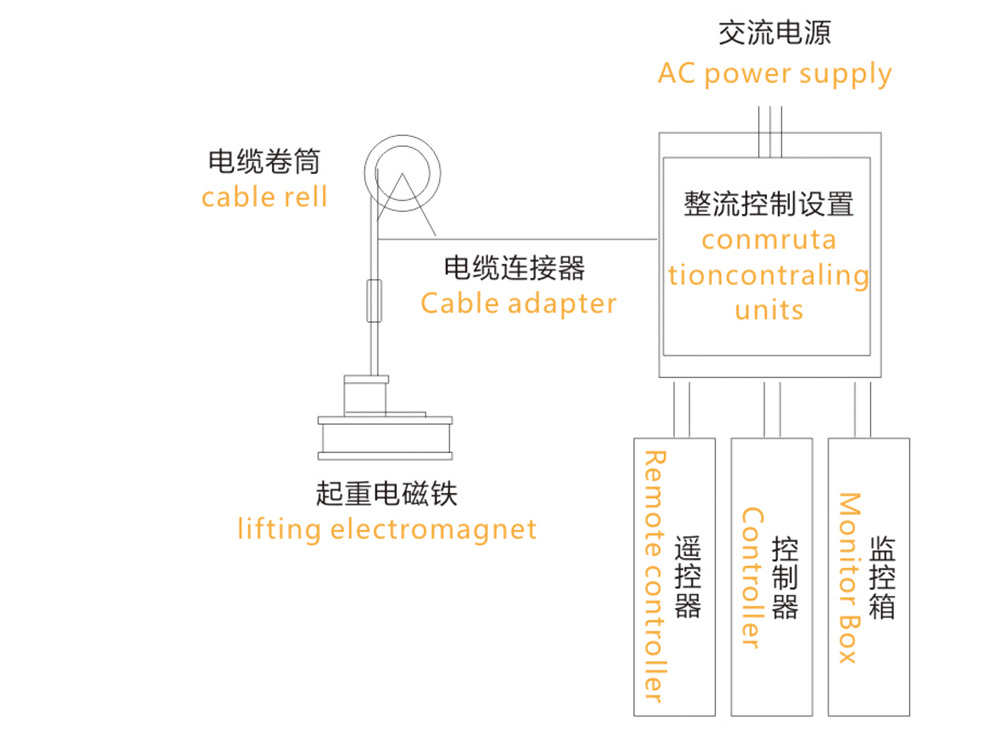

The VT-STQ(0)L three-phase contactless digital control rectifier control device employs a set of fully controlled thyristor power module assemblies to convert the three-phase AC 380V, 50Hz voltage into a DC voltage, providing forward excitation current to the lifting electromagnet. At the same time, this same assembly feeds the residual energy from the electromagnet after material release back into the power grid. Another set of two-phase fully controlled thyristor power module assemblies converts the three-phase AC 380V, 50Hz voltage into a different DC voltage, supplying reverse demagnetizing current to the lifting electromagnet. The operating states of these two sets of thyristor power module assemblies are controlled by a microcontroller-based digital controller. The microcontroller digital controller also coordinates the system’s material pickup and release operations, thereby achieving precise control over the electromagnet’s material pickup, release, and magnetic field adjustment.

Its main technical features

1. There are three working modes.

(1). Constant voltage operation mode: The output voltage is DC 220V;

(2). Magnetic adjustment mode: Output voltage DCOV-DC220V is adjustable;

(3) Strong Excitation Operating Mode: At the moment of lifting, the output voltage is DC 290V; after the material is lifted, the output voltage during the transportation process is DC 200V.

2. There are three operation modes.

(1). Controller or monitoring box operation mode;

(2) Switching signal remote control mode (magnetic adjustment cannot be remotely controlled);

(3) Fully remote-controlled operation for both digital and analog signals (remote magnetic adjustment available);

3. Employing contactless control, this system abandons the traditional DC contactor-based method for magnetization and demagnetization. As a result, there are no electric sparks, no noise, and no mechanical vibrations during operation, thereby extending the service life. During demagnetization, the residual energy stored in the electromagnet is first fed back into the power grid. On the one hand, this eliminates the energy-consuming approach of using high-power resistors to maintain current flow; on the other hand, during lifting, a strong excitation magnetic field is used to firmly attract the material. After lifting, the material is held in place by a low-voltage permanent magnetism. These two measures together achieve significant energy savings.

4. Utilizing the latest microcontrollers for digital, contactless control, this system features button-operated function and parameter settings. Fault alarms and interface parameters are displayed on an LCD screen, and set parameters are automatically saved. The phase shifting, pulse width regulation, and modulation of the pulses have all been digitized. During operation, the trigger section requires no adjustments whatsoever. This system boasts high reliability, strong anti-interference capability, rapid response speed, and ease of use. The equipment is equipped with automatic phase detection, phase-loss protection, soft start upon power-on, as well as protection functions against short circuits, overcurrent, and overvoltage.

5. Integrated modular design and production, utilizing programmable controller technology, and featuring exclusively advanced international or domestic brands. Internal components are modular and arranged in a rational manner, minimizing external wiring while ensuring convenient connection and disconnection of cables. All components can be replaced from the front panel, making maintenance and troubleshooting easy for users. The equipment boasts high operational reliability and safety, with a low failure rate.

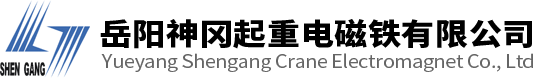

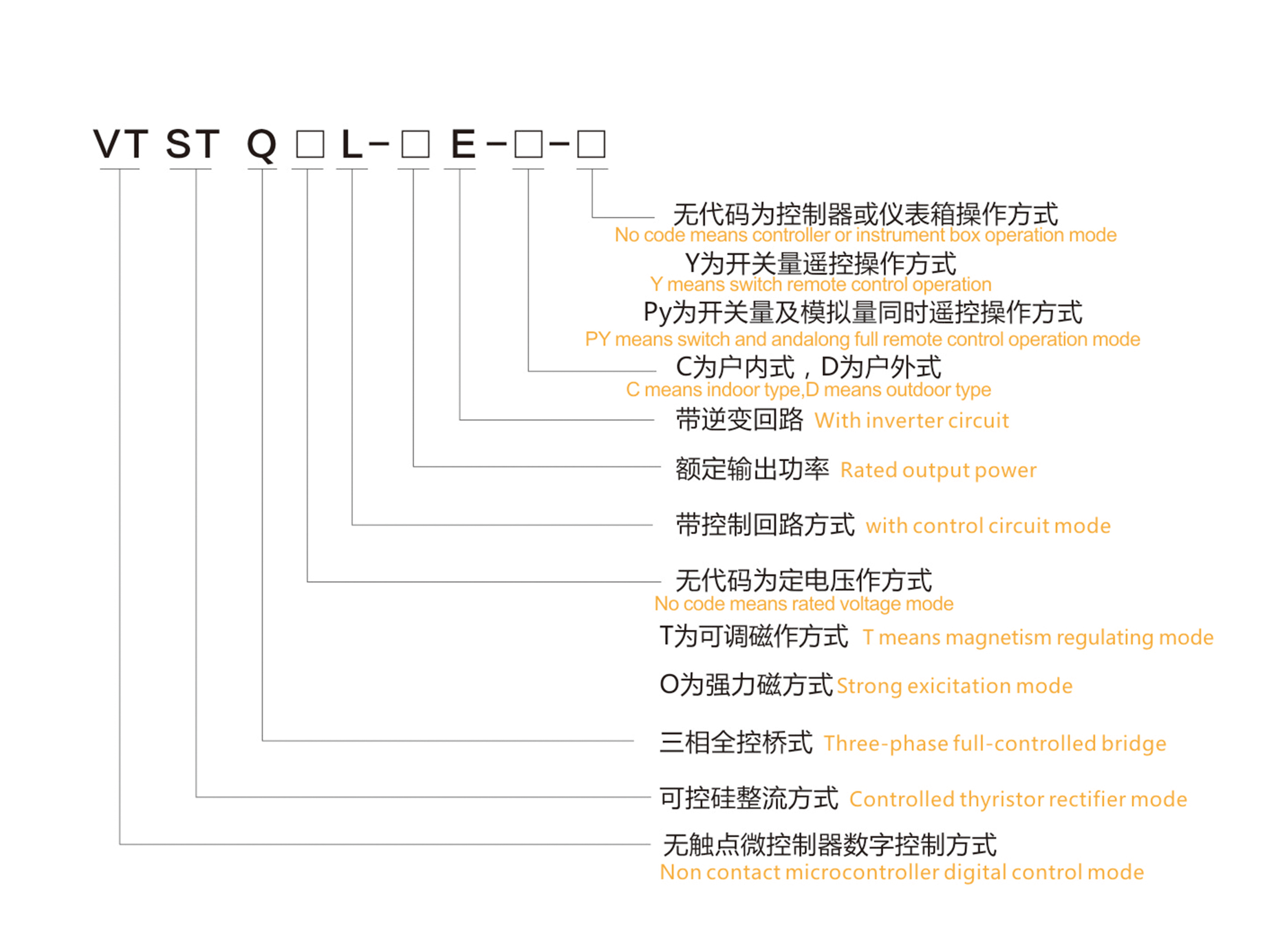

Model Description

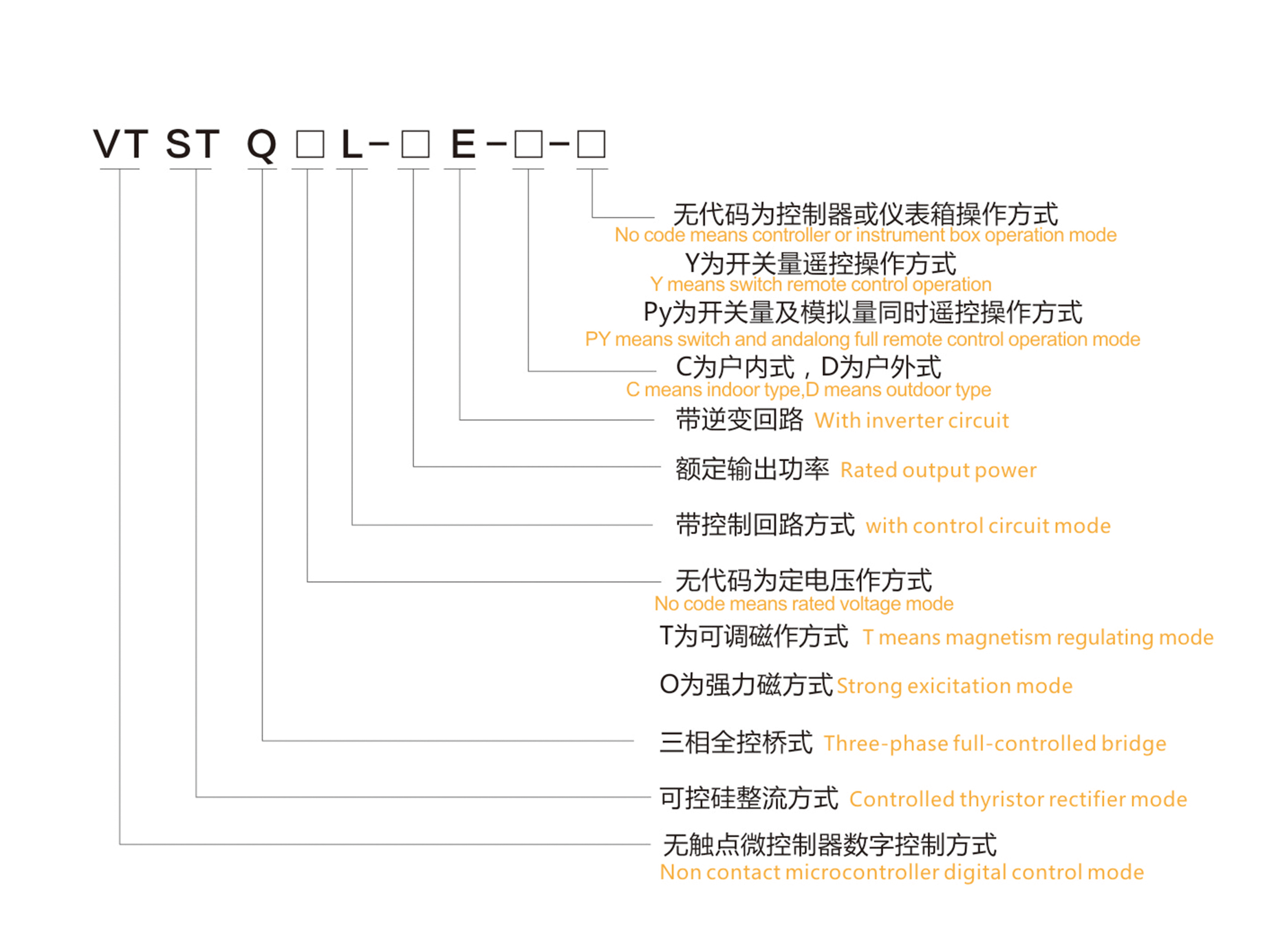

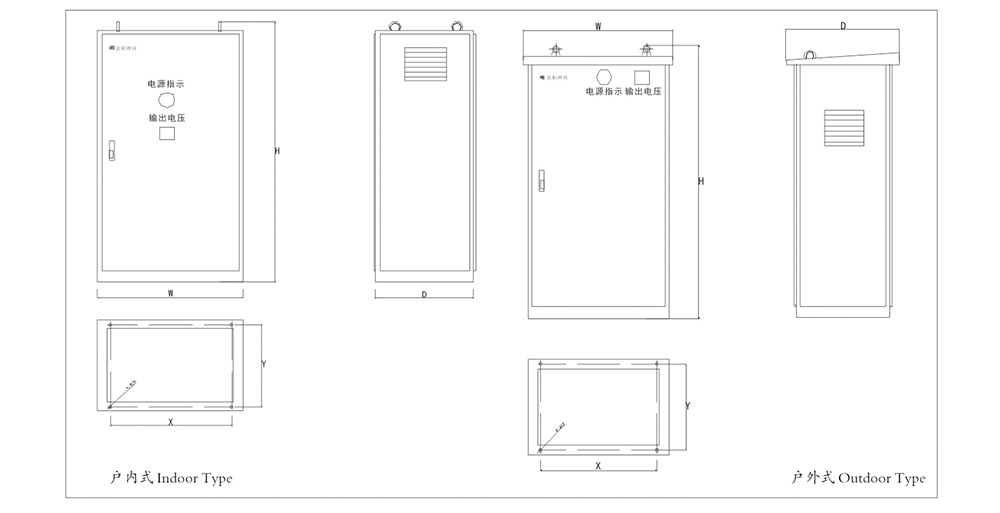

External dimensions

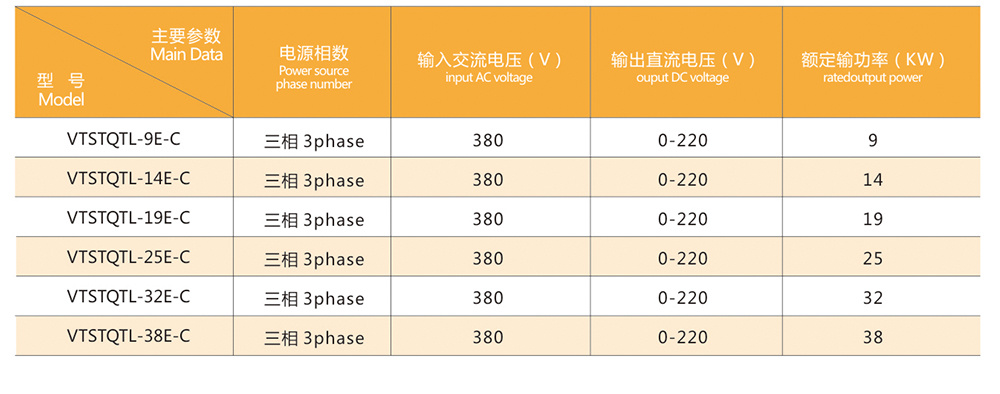

Main Technical Parameters of the Contactless Constant Voltage Rectifier Control Cabinet [For reference only]

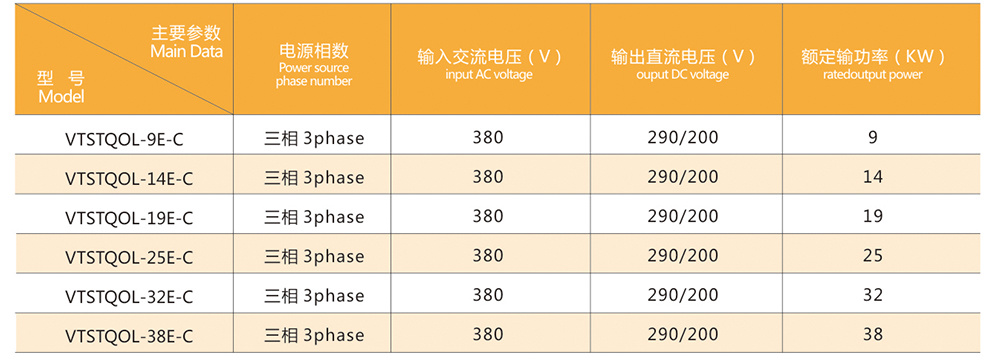

Main Technical Parameters of the Contactless Magnetic Field Regulation Rectifier Control Cabinet [For reference only]

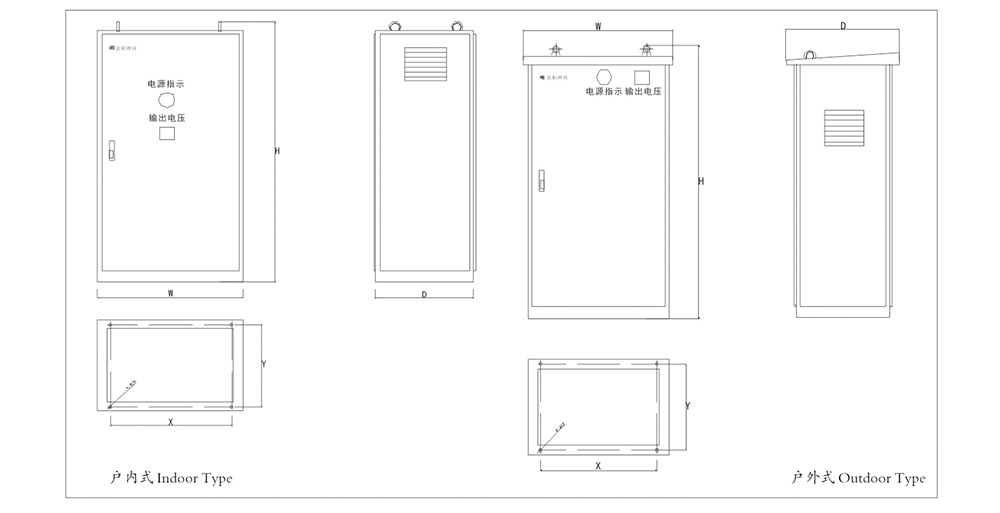

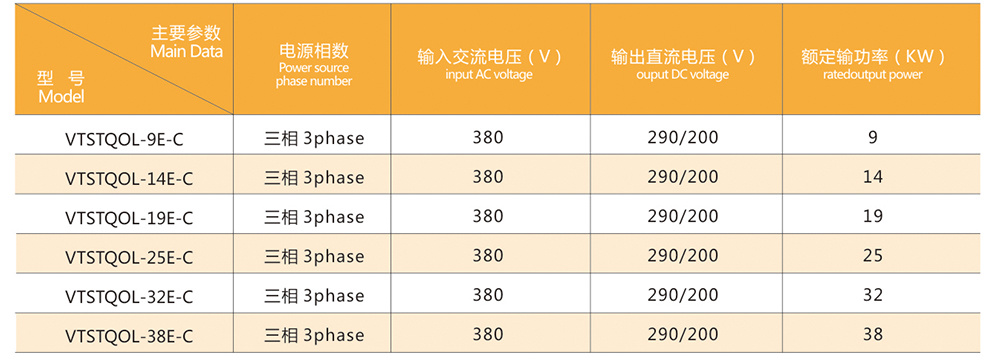

VTSTQOL-E—Non-Contact Strong Excitation Rectifier Control Cabinet: Main Technical Parameters [For reference only]

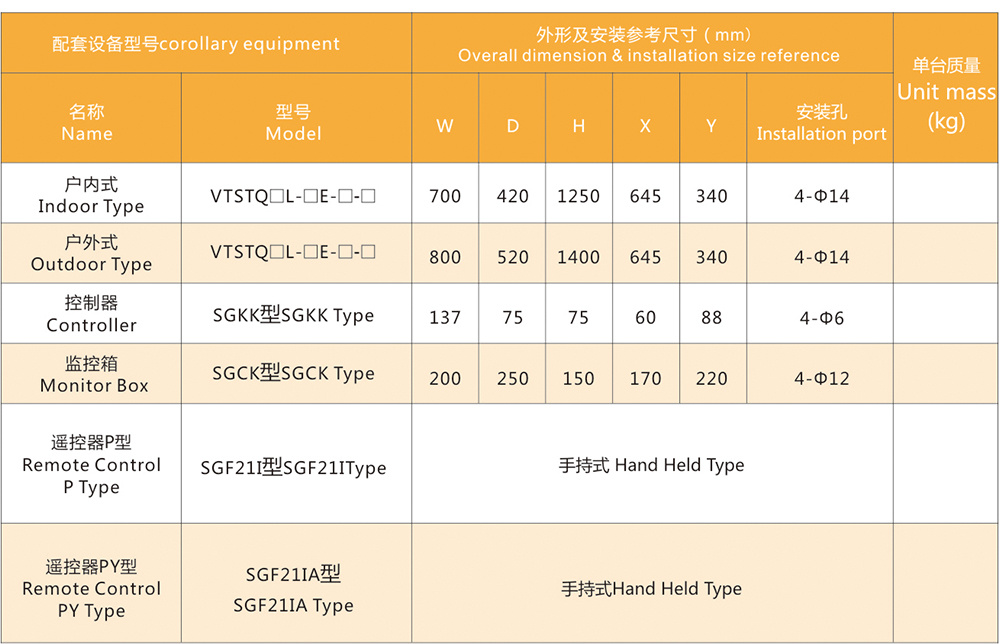

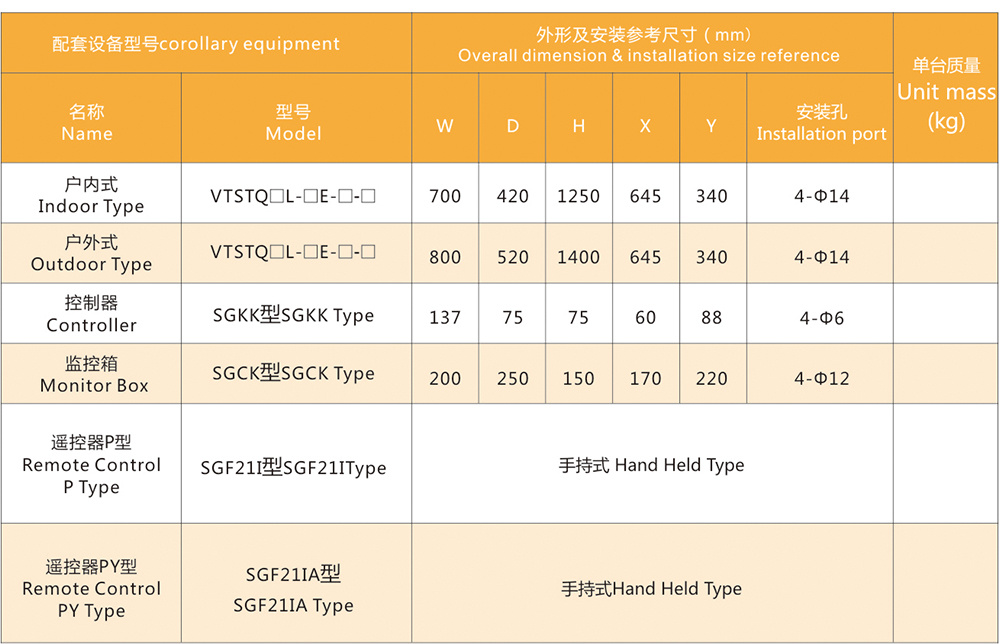

Equipment Completeness and Reference Dimensions for External Installation

The VT-STQ(0)L three-phase contactless digital control rectifier control device employs a set of fully controlled thyristor power module assemblies to convert the three-phase AC 380V, 50Hz voltage into a DC voltage, providing forward excitation current to the lifting electromagnet. At the same time, this same assembly feeds the residual energy from the electromagnet after material release back into the power grid. Another set of two-phase fully controlled thyristor power module assemblies converts the three-phase AC 380V, 50Hz voltage into a different DC voltage, supplying reverse demagnetizing current to the lifting electromagnet. The operating states of these two sets of thyristor power module assemblies are controlled by a microcontroller-based digital controller. The microcontroller digital controller also coordinates the system’s material pickup and release operations, thereby achieving precise control over the electromagnet’s material pickup, release, and magnetic field adjustment.

Its main technical features

1. There are three working modes.

(1). Constant voltage operation mode: The output voltage is DC 220V;

(2). Magnetic adjustment mode: Output voltage DCOV-DC220V is adjustable;

(3) Strong Excitation Operating Mode: At the moment of lifting, the output voltage is DC 290V; after the material is lifted, the output voltage during the transportation process is DC 200V.

2. There are three operation modes.

(1). Controller or monitoring box operation mode;

(2) Switching signal remote control mode (magnetic adjustment cannot be remotely controlled);

(3) Fully remote-controlled operation for both digital and analog signals (remote magnetic adjustment available);

3. Employing contactless control, this system abandons the traditional DC contactor-based method for magnetization and demagnetization. As a result, there are no electric sparks, no noise, and no mechanical vibrations during operation, thereby extending the service life. During demagnetization, the residual energy stored in the electromagnet is first fed back into the power grid. On the one hand, this eliminates the energy-consuming approach of using high-power resistors to maintain current flow; on the other hand, during lifting, a strong excitation magnetic field is used to firmly attract the material. After lifting, the material is held in place by a low-voltage permanent magnetism. These two measures together achieve significant energy savings.

4. Utilizing the latest microcontrollers for digital, contactless control, this system features button-operated function and parameter settings. Fault alarms and interface parameters are displayed on an LCD screen, and set parameters are automatically saved. The phase shifting, pulse width regulation, and modulation of the pulses have all been digitized. During operation, the trigger section requires no adjustments whatsoever. This system boasts high reliability, strong anti-interference capability, rapid response speed, and ease of use. The equipment is equipped with automatic phase detection, phase-loss protection, soft start upon power-on, as well as protection functions against short circuits, overcurrent, and overvoltage.

5. Integrated modular design and production, utilizing programmable controller technology, and featuring exclusively advanced international or domestic brands. Internal components are modular and arranged in a rational manner, minimizing external wiring while ensuring convenient connection and disconnection of cables. All components can be replaced from the front panel, making maintenance and troubleshooting easy for users. The equipment boasts high operational reliability and safety, with a low failure rate.

Model Description

External dimensions

Main Technical Parameters of the Contactless Constant Voltage Rectifier Control Cabinet [For reference only]

Main Technical Parameters of the Contactless Magnetic Field Regulation Rectifier Control Cabinet [For reference only]

VTSTQOL-E—Non-Contact Strong Excitation Rectifier Control Cabinet: Main Technical Parameters [For reference only]

Equipment Completeness and Reference Dimensions for External Installation

Key words:

Electromagnetic equipment manufacturing, multi-function lifting electromagnet, special lifting electromagnet, multi-purpose lifting electromagnet, permanent magnet coupling hysteresis head

Next Page

RELATED PRODUCTS

This series is designed for lifting and handling cast iron ingots, steel balls, pig iron blocks, machined chips; return materials, iron concentrate powder, cut-off ends; packaged scrap steel, and more. The excitation methods available include: rated voltage DC 220V mode; and strong excitation mode—over-excitation mode.

This series features oval-shaped lifting electromagnets, primarily used for efficiently loading and unloading scrap steel in narrow vehicle compartments. Customization is available based on the specific dimensions of the vehicle compartment.

This series features the most widely used rectangular electromagnets, primarily suited for lifting billets, ingots, and large initial rolling billets. They can also be used for lifting round billets and structural steel. Different magnetic circuit designs are employed to accommodate various types of steel.

Online consultation

The company will continue to develop and innovate with the enterprise spirit of worrying about customers first and enjoying the happiness of customers later, and strive to become a giant of modern enterprises. Welcome all friends to visit and guide our company!

Address: Liji Avenue, Junshan Industrial Park, Yueyang City, Hunan Province

Fax: 0730-8647119