Products

-

-

Raw billets, beam billets, and plate billets are lifted using electric lifting magnets.

-

Specialized Lifting Electromagnet for High-Speed Wire (Coil)

-

Pipe blanks, steel pipes, large round blanks for lifting with electric lifting magnets

-

Heavy rail, steel pipe lifting with electric lifting magnets

-

Medium-thick steel plate lifting with electric lifting magnet

-

Medium-thick steel plate multi-sheet lifting special lifting electromagnet

RELATED INFORMATION

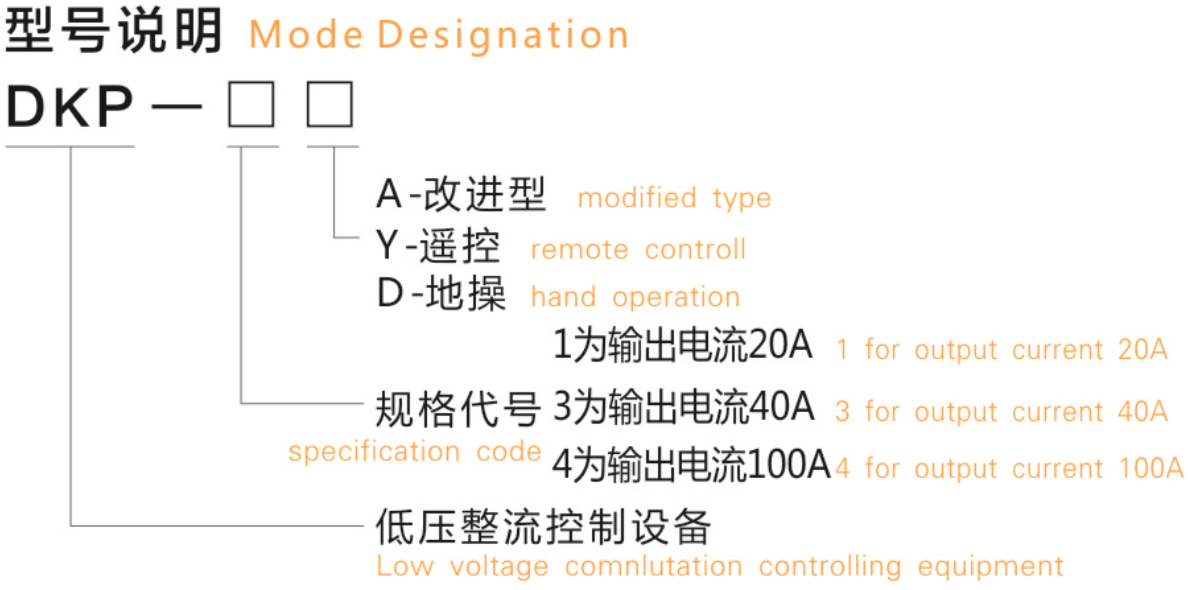

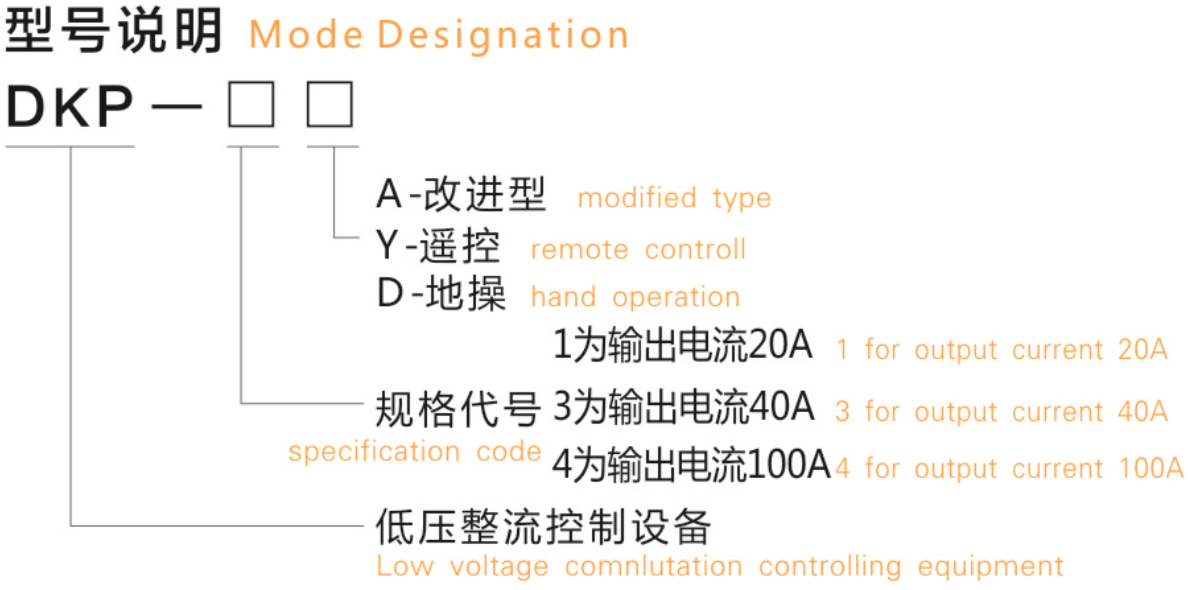

DKP Series Rectifier Control Equipment

This product series employs a three-wire, two-phase half-wave rectification method. During material discharge, it utilizes the energy stored in an electromagnet to control reverse demagnetization. This product features a simple circuit design, a compact structure, small size, and light weight.

Classification:

E-mail:hnyysg0730@163.com

Case Details

This product series employs a three-wire, two-phase half-wave rectification method. During material discharge, it utilizes the energy stored in an electromagnet to control reverse demagnetization. This product features a simple circuit design, a compact structure, small size, and light weight.

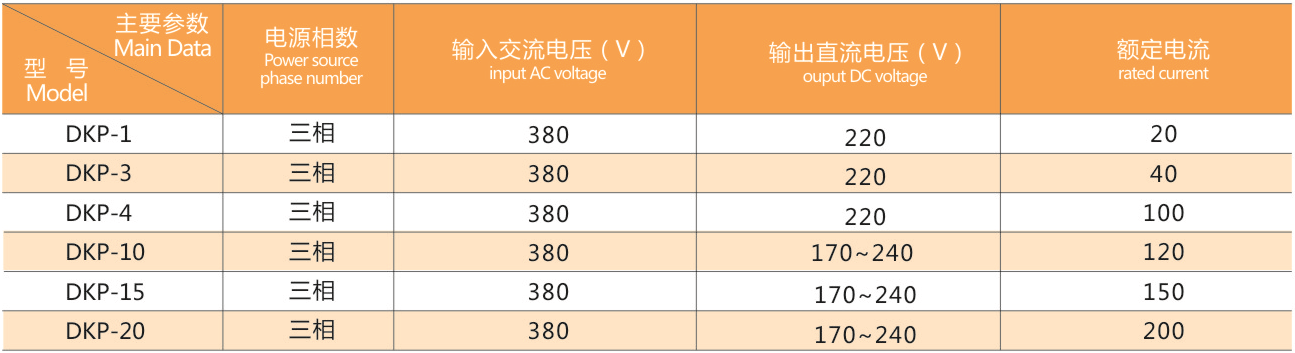

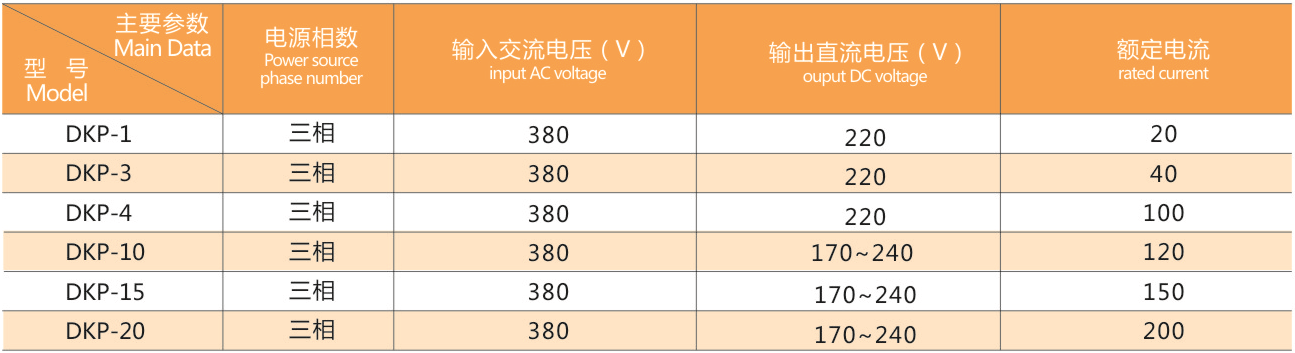

Main Technical Parameters [For reference only]

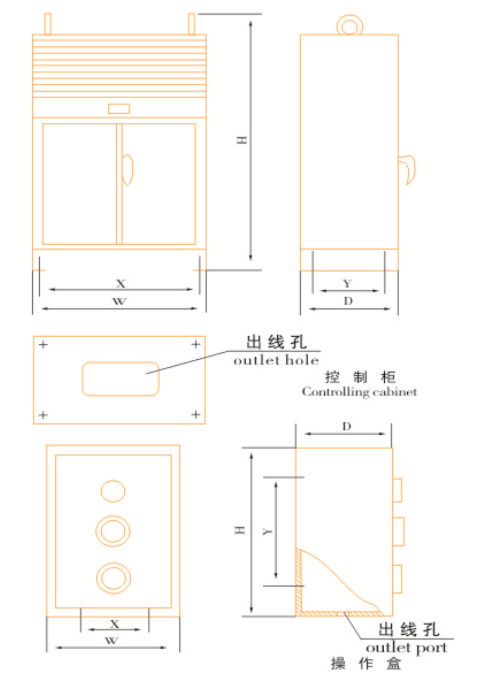

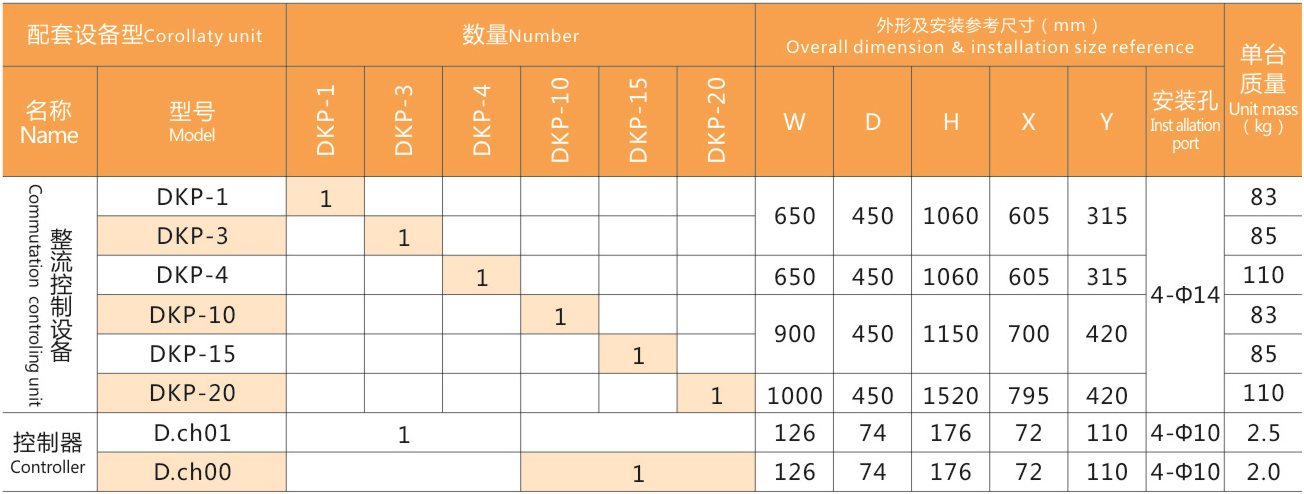

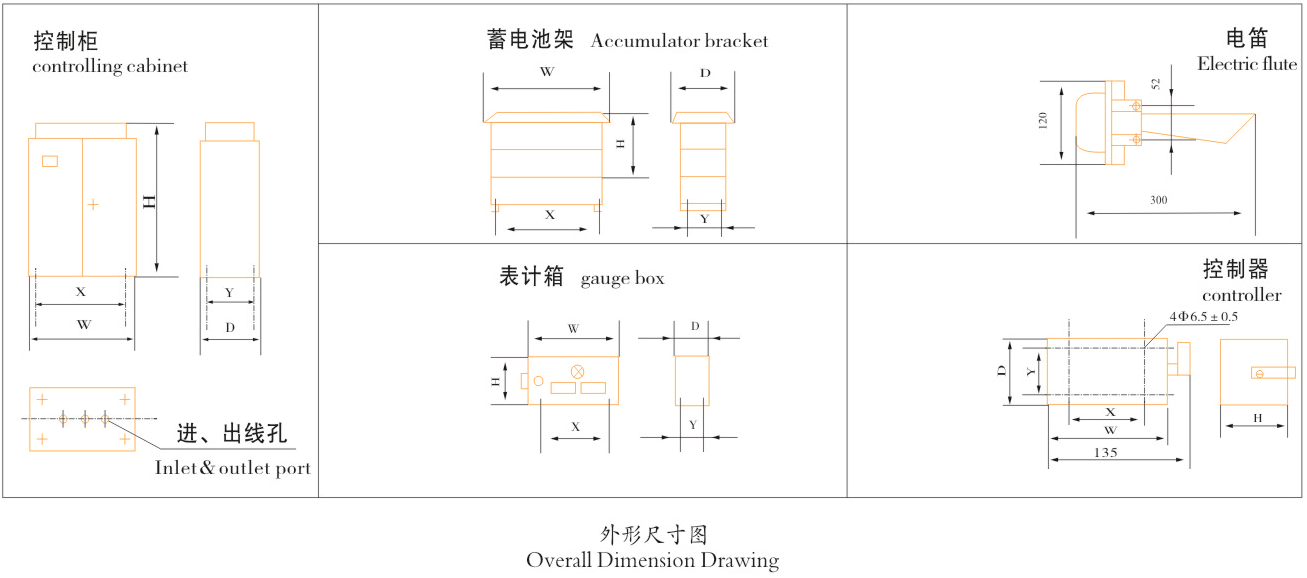

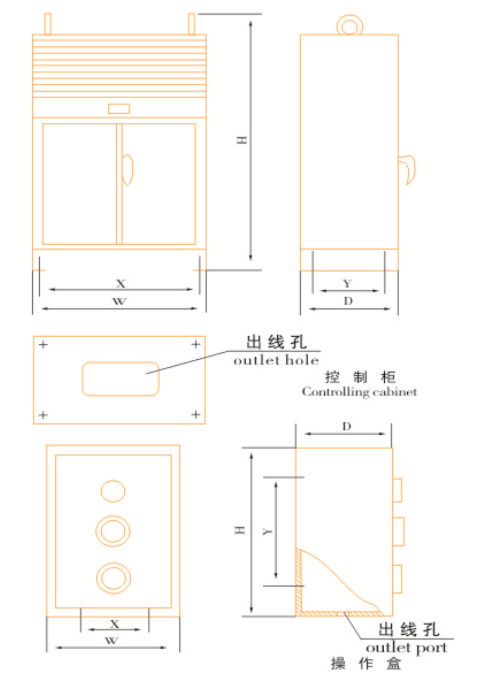

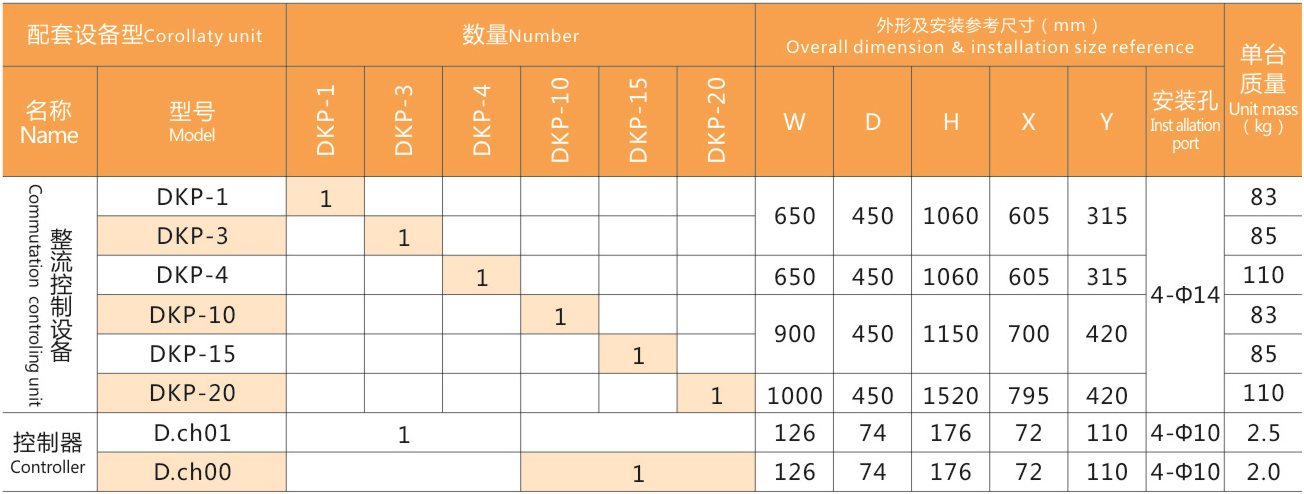

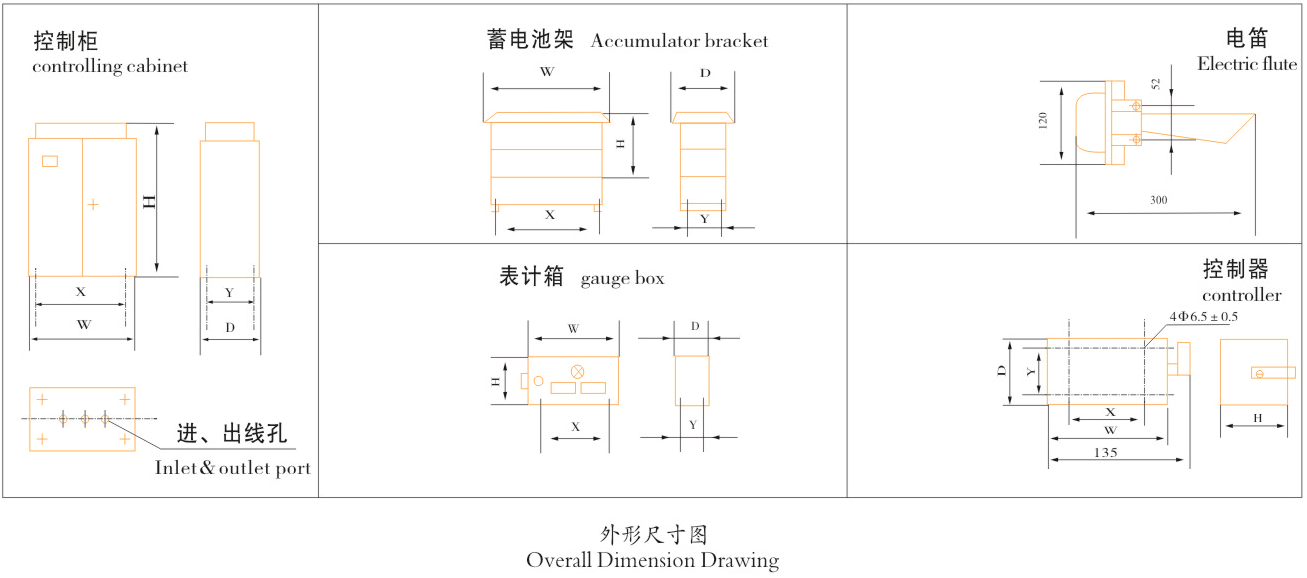

Reference Dimensions for Supporting Equipment and External Installation

Note: 1. DKP-1, DKP-3, and DKP-4 are half-wave rectifier control devices of the three-wire, two-phase type.

2. DKP-1A, DKP-3A, and DKP-4A are three-wire, two-phase, half-wave controlled rectifier control devices. When the grid voltage is too high or too low, adjusting the potentiometer allows the output voltage to be adjusted within the range of 170 V to 240 V, thereby bringing the output voltage close to approximately 220 V.

Power-off magnetic retention device

There are two series of power-off magnetic retention devices: the GTBM series is suitable for applications that use conventional constant-voltage control; the GTBMT series not only features power-off magnetic retention but also includes magnetic-field adjustment capability. By freely adjusting the excitation voltage of the electromagnet, users can easily control the number of steel plates being attracted or released. These two series represent our company’s technological upgrade and retrofit of the original GTB6 and LPB1 product lines, enhancing the reliability and technological sophistication of the original series and significantly reducing the maintenance workload for users.

Main features

1. In the event of a sudden power outage during operation, the system will automatically switch to backup power, ensuring that the suspended object does not fall within the set time frame. Additionally, the winch’s brake can be released, allowing the suspended object to be safely lowered.

2. The equipment features excellent completeness and is equipped with dedicated charging devices as well as comprehensive display, detection, and alarm systems.

3. It uses valve-regulated, fully sealed, maintenance-free lead-acid batteries that require no manual supervision during charging. The system automatically switches charging modes based on battery status monitoring, ensuring a long service life.

4. The device is lightweight and requires no special installation requirements; it’s easy to maintain and service.

Power-off magnetic retention device

Selection and Precautions

1. The rated voltage of the electromagnet must match the output voltage of the equipment; the sum of the currents (power consumption) of the electromagnets should be less than or equal to the output current (power) of the rectifier control device.

2. The winch brake配套 with this equipment must be a DC electromagnetic brake (ZWZ400-400). If an AC brake is used instead, an UPS inverter must be installed.

3. If the operating environment temperature exceeds 40℃, or if there are special requirements such as modification or capacity expansion, please specify this when placing your order.

This product series employs a three-wire, two-phase half-wave rectification method. During material discharge, it utilizes the energy stored in an electromagnet to control reverse demagnetization. This product features a simple circuit design, a compact structure, small size, and light weight.

Main Technical Parameters [For reference only]

Reference Dimensions for Supporting Equipment and External Installation

Note: 1. DKP-1, DKP-3, and DKP-4 are half-wave rectifier control devices of the three-wire, two-phase type.

2. DKP-1A, DKP-3A, and DKP-4A are three-wire, two-phase, half-wave controlled rectifier control devices. When the grid voltage is too high or too low, adjusting the potentiometer allows the output voltage to be adjusted within the range of 170 V to 240 V, thereby bringing the output voltage close to approximately 220 V.

Power-off magnetic retention device

There are two series of power-off magnetic retention devices: the GTBM series is suitable for applications that use conventional constant-voltage control; the GTBMT series not only features power-off magnetic retention but also includes magnetic-field adjustment capability. By freely adjusting the excitation voltage of the electromagnet, users can easily control the number of steel plates being attracted or released. These two series represent our company’s technological upgrade and retrofit of the original GTB6 and LPB1 product lines, enhancing the reliability and technological sophistication of the original series and significantly reducing the maintenance workload for users.

Main features

1. In the event of a sudden power outage during operation, the system will automatically switch to backup power, ensuring that the suspended object does not fall within the set time frame. Additionally, the winch’s brake can be released, allowing the suspended object to be safely lowered.

2. The equipment features excellent completeness and is equipped with dedicated charging devices as well as comprehensive display, detection, and alarm systems.

3. It uses valve-regulated, fully sealed, maintenance-free lead-acid batteries that require no manual supervision during charging. The system automatically switches charging modes based on battery status monitoring, ensuring a long service life.

4. The device is lightweight and requires no special installation requirements; it’s easy to maintain and service.

Power-off magnetic retention device

Selection and Precautions

1. The rated voltage of the electromagnet must match the output voltage of the equipment; the sum of the currents (power consumption) of the electromagnets should be less than or equal to the output current (power) of the rectifier control device.

2. The winch brake配套 with this equipment must be a DC electromagnetic brake (ZWZ400-400). If an AC brake is used instead, an UPS inverter must be installed.

3. If the operating environment temperature exceeds 40℃, or if there are special requirements such as modification or capacity expansion, please specify this when placing your order.

Key words:

Electromagnetic equipment manufacturing, multi-function lifting electromagnet, special lifting electromagnet, multi-purpose lifting electromagnet, permanent magnet coupling hysteresis head

RELATED PRODUCTS

This series is designed for lifting and handling cast iron ingots, steel balls, pig iron blocks, machined chips; return materials, iron concentrate powder, cut-off ends; packaged scrap steel, and more. The excitation methods available include: rated voltage DC 220V mode; and strong excitation mode—over-excitation mode.

This series features oval-shaped lifting electromagnets, primarily used for efficiently loading and unloading scrap steel in narrow vehicle compartments. Customization is available based on the specific dimensions of the vehicle compartment.

This series features the most widely used rectangular electromagnets, primarily suited for lifting billets, ingots, and large initial rolling billets. They can also be used for lifting round billets and structural steel. Different magnetic circuit designs are employed to accommodate various types of steel.

Online consultation

The company will continue to develop and innovate with the enterprise spirit of worrying about customers first and enjoying the happiness of customers later, and strive to become a giant of modern enterprises. Welcome all friends to visit and guide our company!

Address: Liji Avenue, Junshan Industrial Park, Yueyang City, Hunan Province

Fax: 0730-8647119